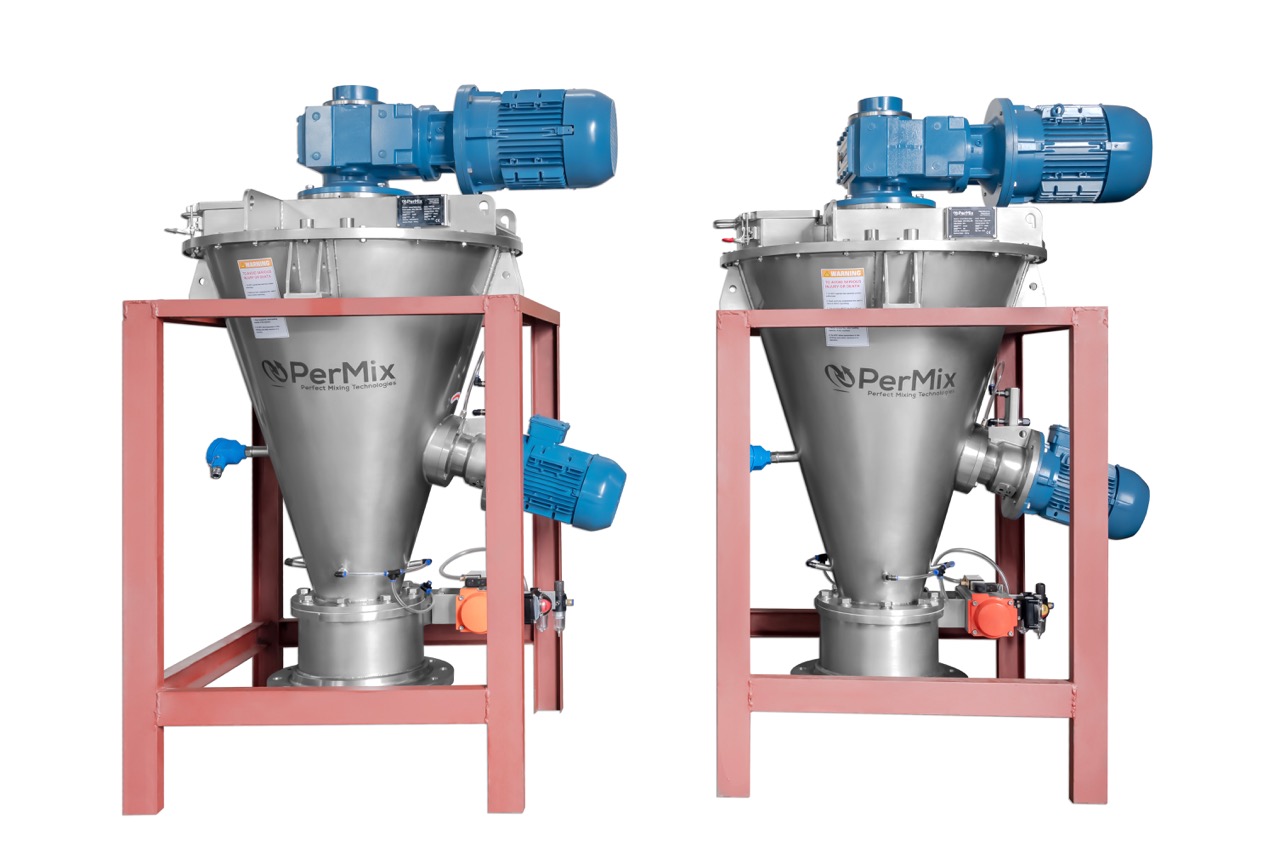

PerMix Vertical Ribbon Mixers

PerMix Vertical Ribbon Mixers are advanced industrial equipment designed for the efficient blending of powders, granules, and other bulk materials in a vertical orientation.

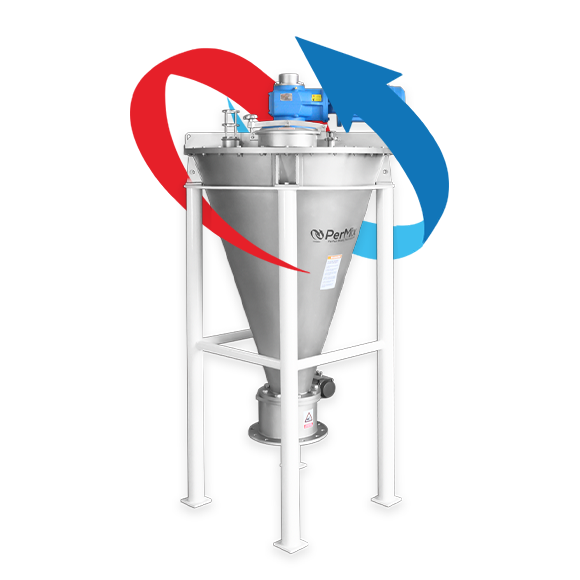

These mixers are engineered to achieve thorough and consistent mixing through the use of a vertical shaft with helical ribbons, providing an optimal solution for various mixing challenges.