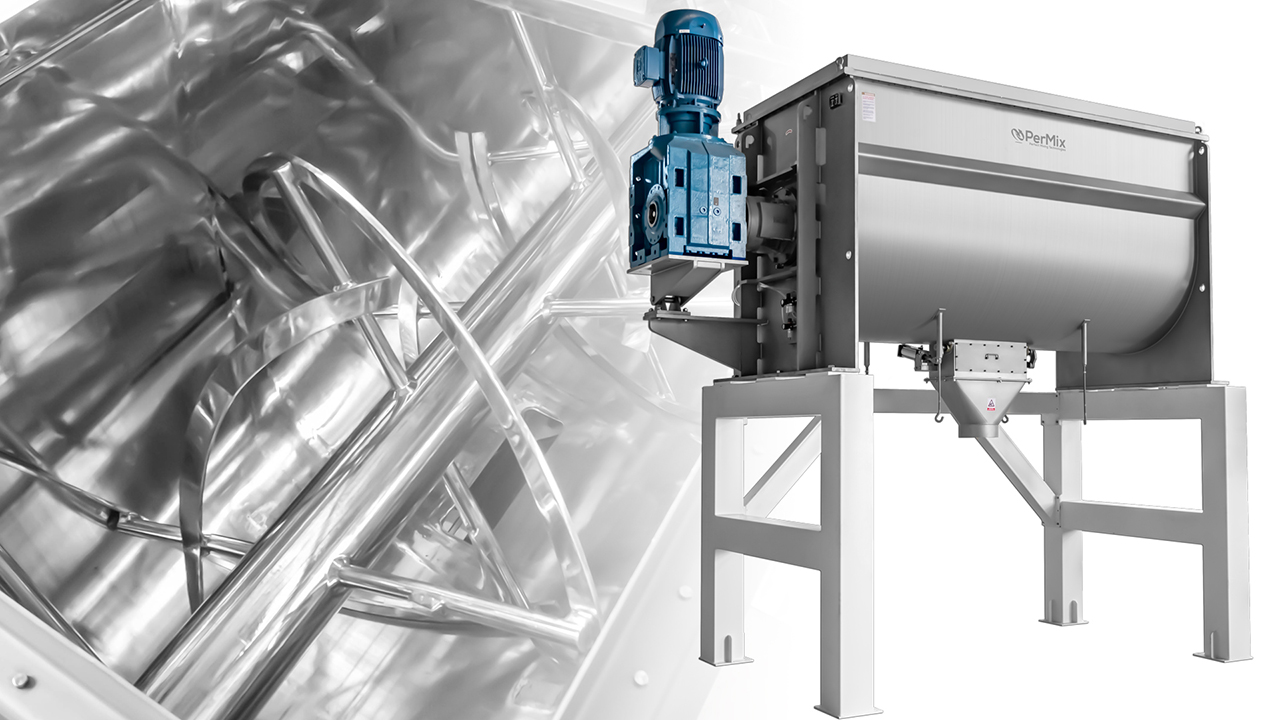

PerMix Horizontal Ribbon Mixers – The Best in Performance, Engineering & Value

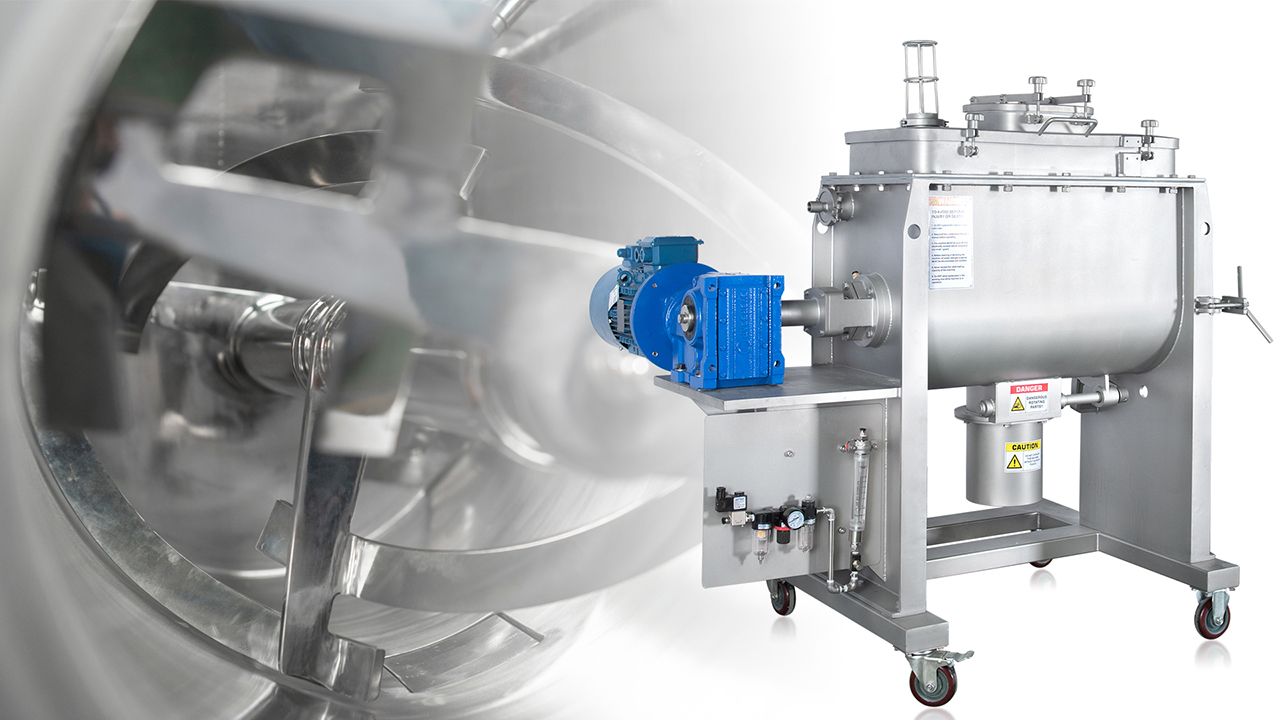

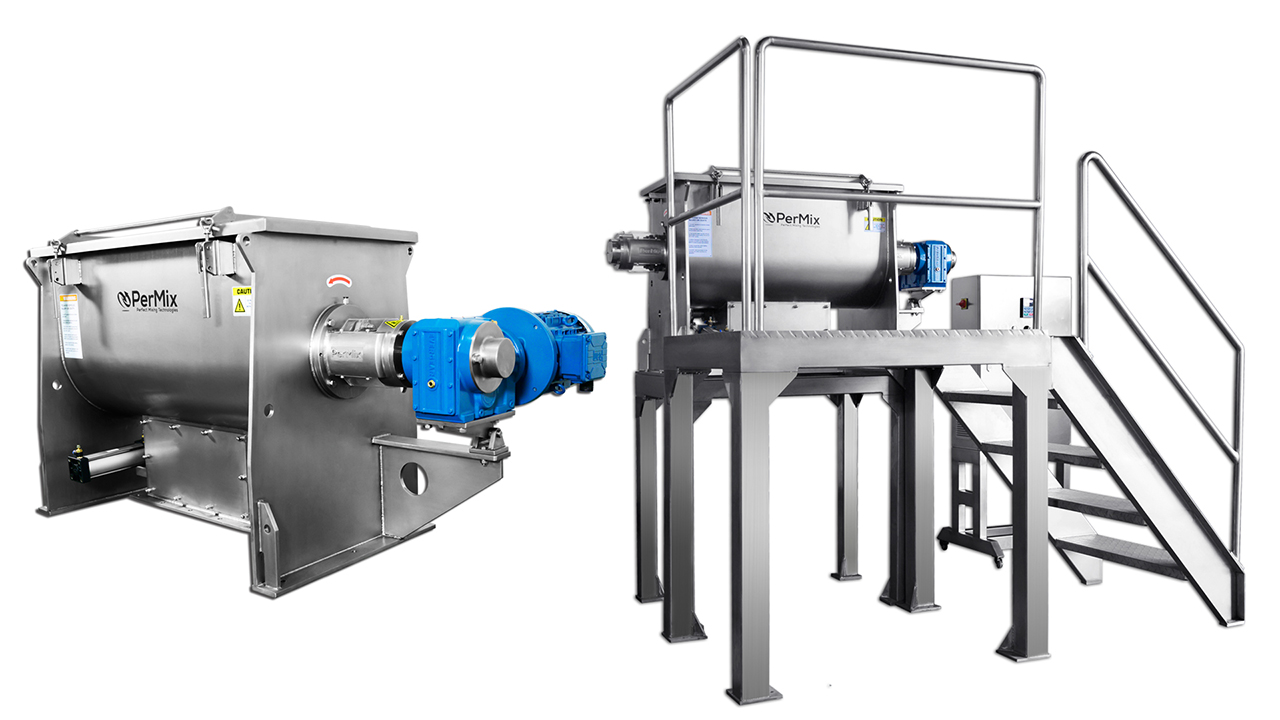

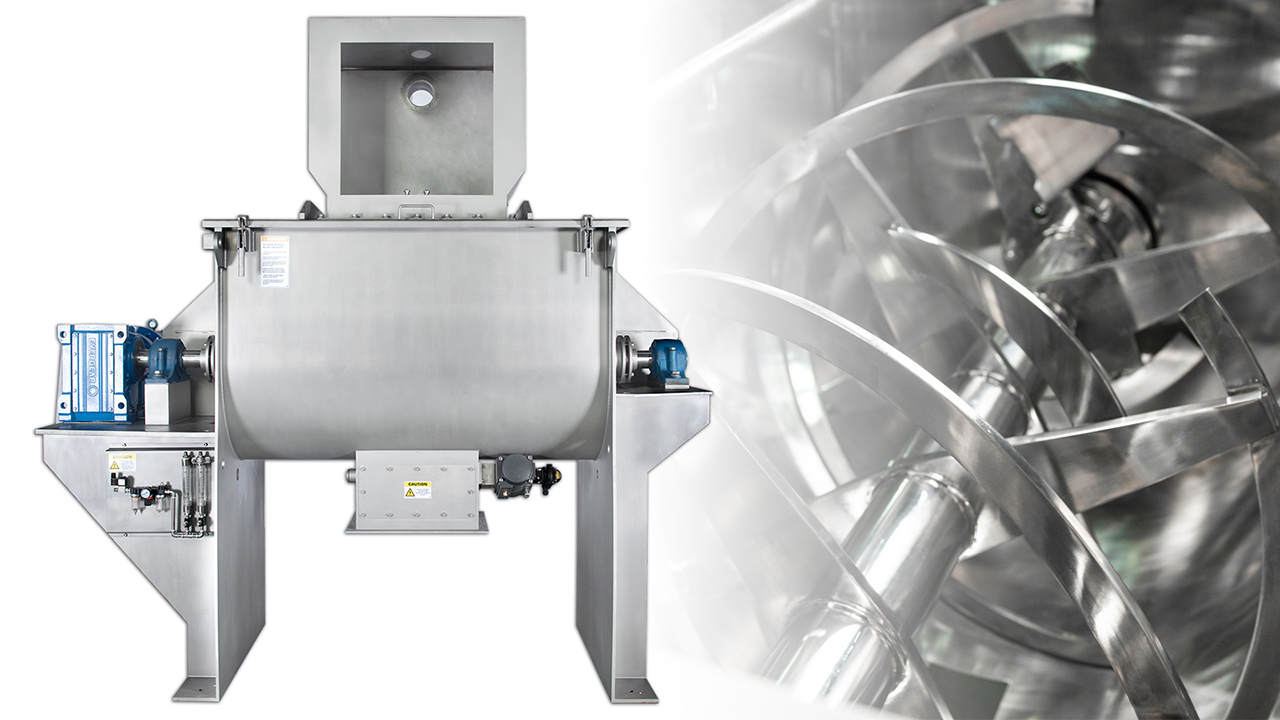

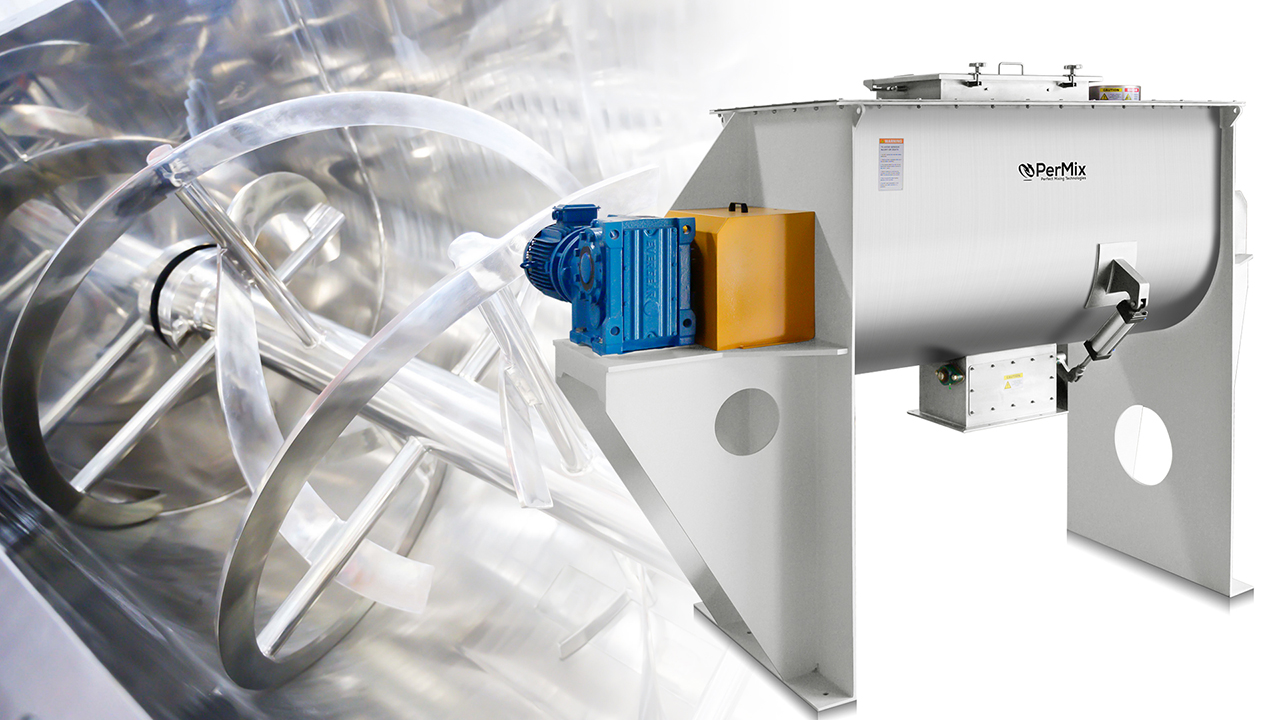

PerMix, we take pride in manufacturing the most efficient, durable, and cost-effective horizontal ribbon mixers on the market. Our commitment to engineering excellence, superior quality, and innovation ensures that our mixers outperform the competition in batch consistency, mixing speed, durability, and ease of use. Whether you’re blending powders, granules, or pastes, our horizontal ribbon mixers provide the ultimate solution for food, pharmaceuticals, chemicals, plastics, and other industries.

Why Choose PerMix Horizontal Ribbon Mixers Over the Competition?

1. Unmatched Engineering & Performance

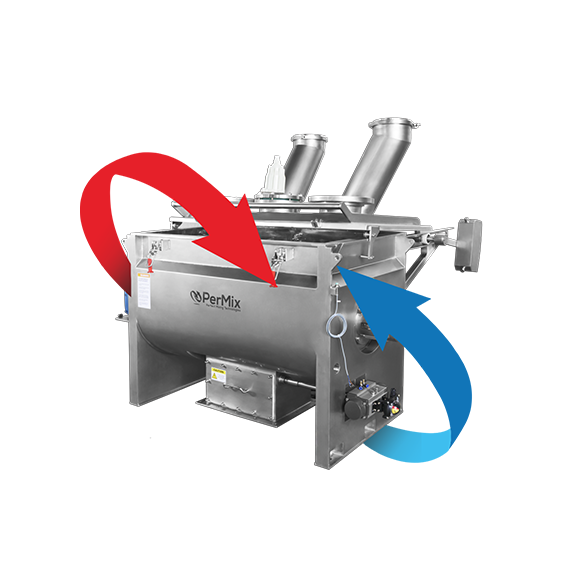

- Fast & Homogeneous Mixing: Our dual helical ribbon design ensures fast, thorough blending with minimal energy consumption.

- Customizable Ribbon Configurations: Standard and specialized ribbon agitator designs optimize mixing for different materials.

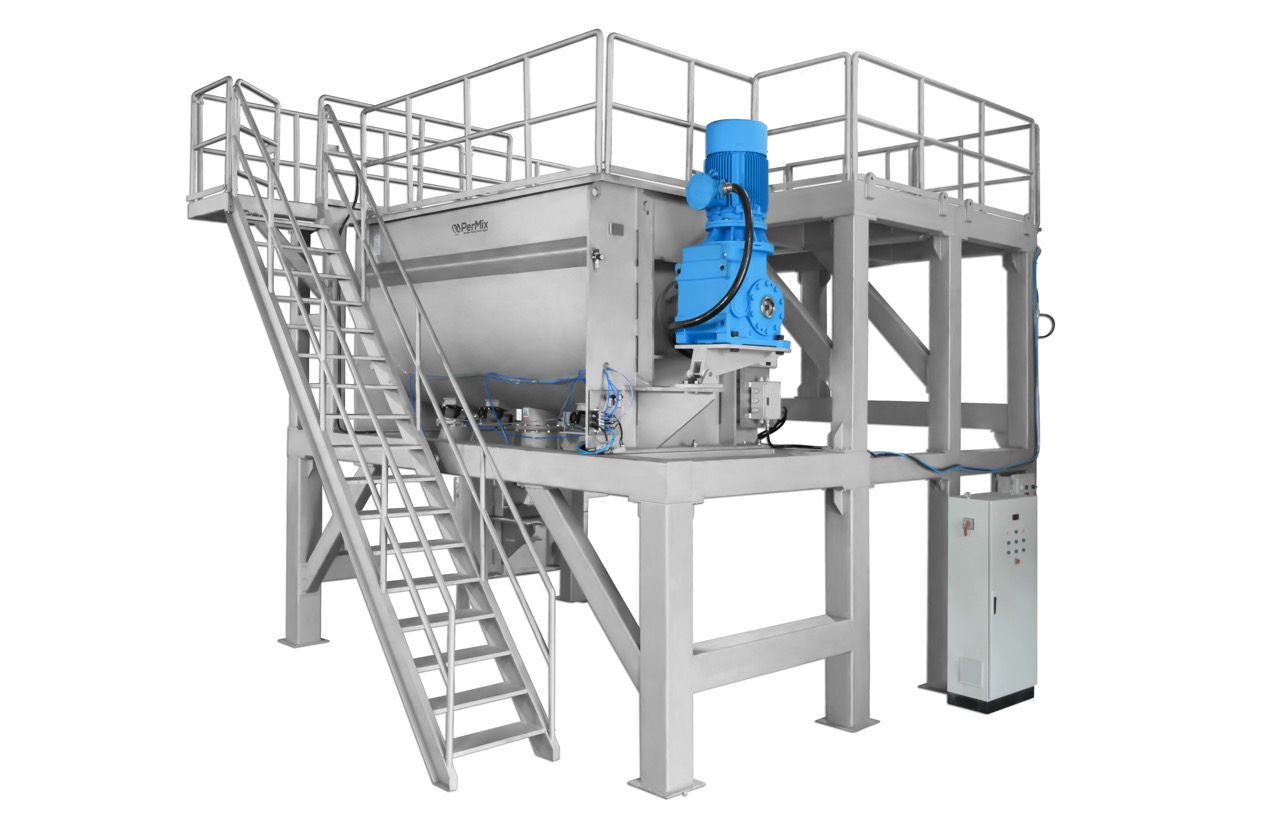

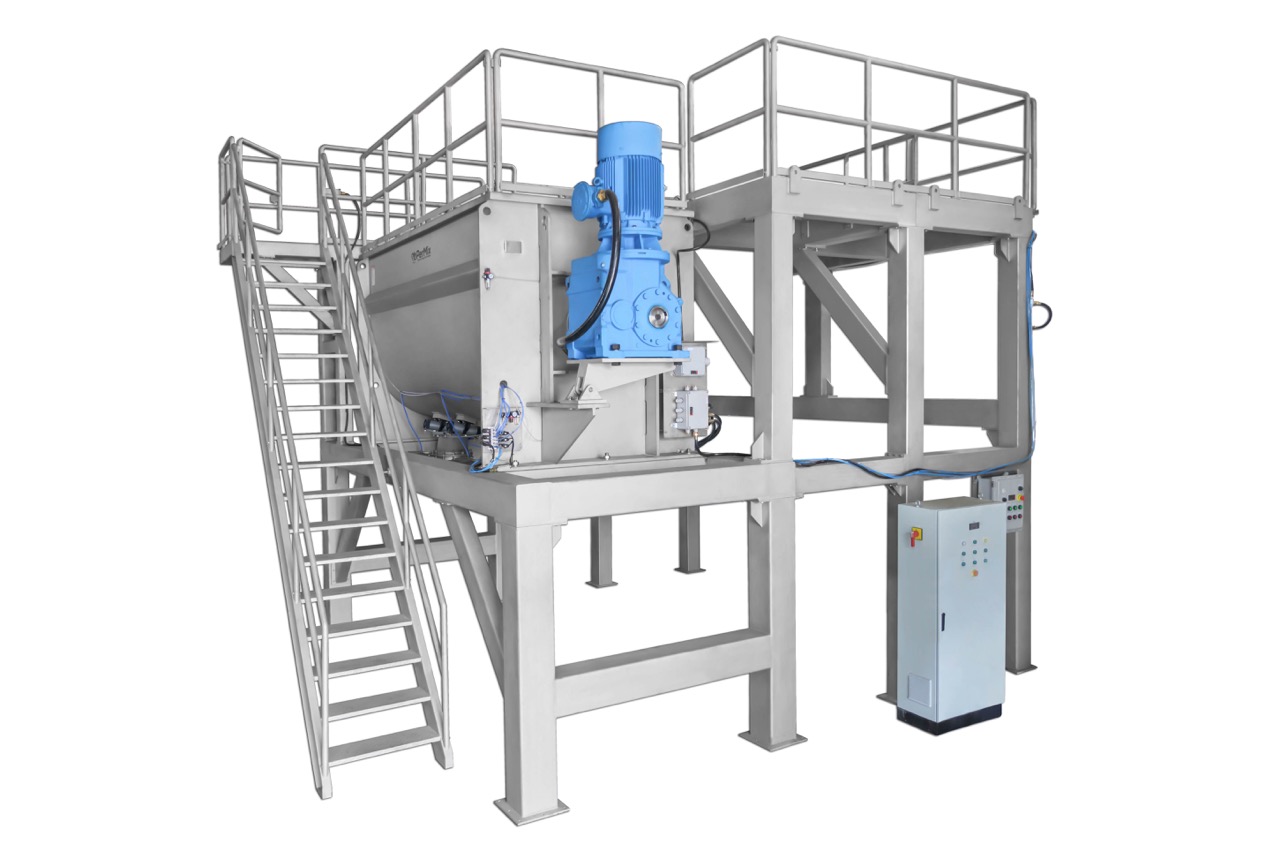

- Scalability: Available in sizes from lab-scale to large-scale production, ensuring seamless process scale-up.

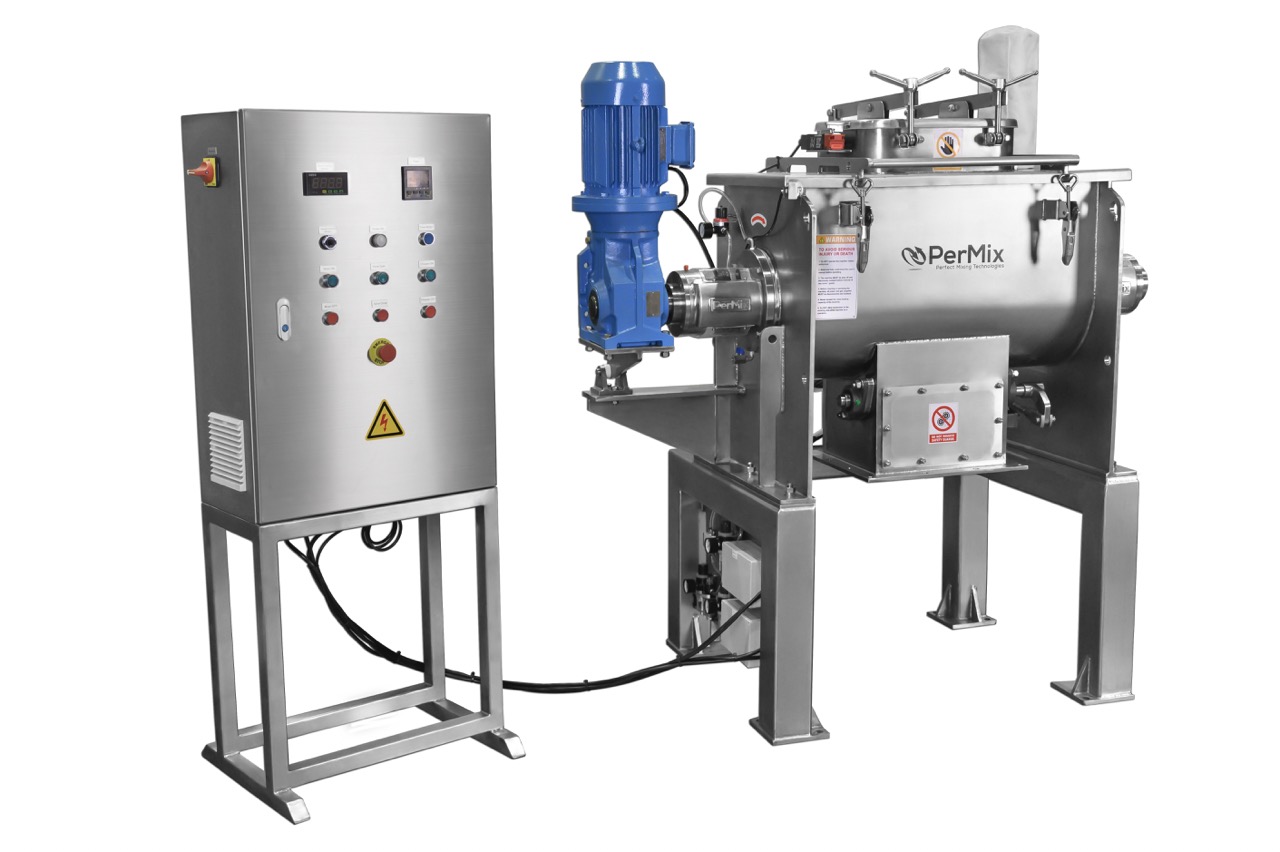

2. Superior Construction & Materials

- Heavy-Duty Design: Made from high-quality stainless steel (304SS, 316SS), Hardox, and even titanium for corrosion resistance and durability.

- Sanitary & Hygienic Build: Our food-grade, pharmaceutical-grade, and hygienic designs exceed industry standards.

- Precision Welding & Polish: Smooth, crevice-free interiors prevent cross-contamination and make cleaning easy.

3. Innovation & Customization – Built for Your Needs

PerMix horizontal ribbon mixers are available with a variety of custom options to fit your specific process needs:

✅ Heating & Cooling Jacket – For precise temperature control during mixing.

✅ Vacuum Mixing & Drying – Ideal for moisture-sensitive or heat-sensitive materials.

✅ Load Cells & Weighing Systems – For precise batch control and recipe management.

✅ Air Purge Shaft Seals – Keep dust & contaminants out for sanitary operations.

✅ Choppers & High-Speed Blades – Break up agglomerates and improve particle distribution.

✅ CIP (Clean-in-Place) System – Fully automated washdown systems for easy cleaning.

4. Best Price-to-Performance Ratio

- More Affordable Than Competitors – Lower total cost of ownership with better durability & longer service life.

- Industry-Leading Warranty – Backed by PerMix’s best-in-class warranty for peace of mind.

- Fast Lead Times & Global Support – We deliver quickly and offer worldwide customer service & technical support.

Industries That Trust PerMix Horizontal Ribbon Mixers

✅ Food & Beverage – Spices, seasoning blends, protein powders, flour blends, dairy powders.

✅ Pharmaceuticals & Nutraceuticals – Powdered supplements, vitamin blends, herbal extracts.

✅ Chemicals & Coatings – Paint powders, resins, chemical additives.

✅ Plastics & Polymers – Masterbatches, PVC compounds, plastic additives.

PerMix vs. The Competition – Why We Win

Many manufacturers offer ribbon mixers, but none match the engineering, performance, and price that PerMix provides. Our mixers are:

✅ More Efficient: Faster mixing times mean higher throughput and increased production efficiency.

✅ More Versatile: Customizable agitators, seals, and discharge options for any industry.

✅ More Cost-Effective: Built to last, competitively priced, and backed by our superior support.

Get a Quote Today & Upgrade to PerMix Quality

If you’re looking for the best horizontal ribbon mixer that delivers performance, durability, and value, PerMix is your solution.

👉 Visit PerMix to learn more.

📩 Contact us today for a free consultation & quote!