Vacuum Ribbon Mixers Are Perfect For Mixing In High Temperatures

Vacuum Ribbon Mixers Are Perfect For High Temperature Mixing & Drying For Explosive & Hazardous Areas

PerMix leads the industry in innovation, performance, quality, & pricing, making us the most disruptive brand. Our approach to giving the customers what they want, at a price they can afford, is winning the hearts of our customers as well as market share in a competitive global market. Since 1954 we have been providing mixing solutions for all applications across all industries.

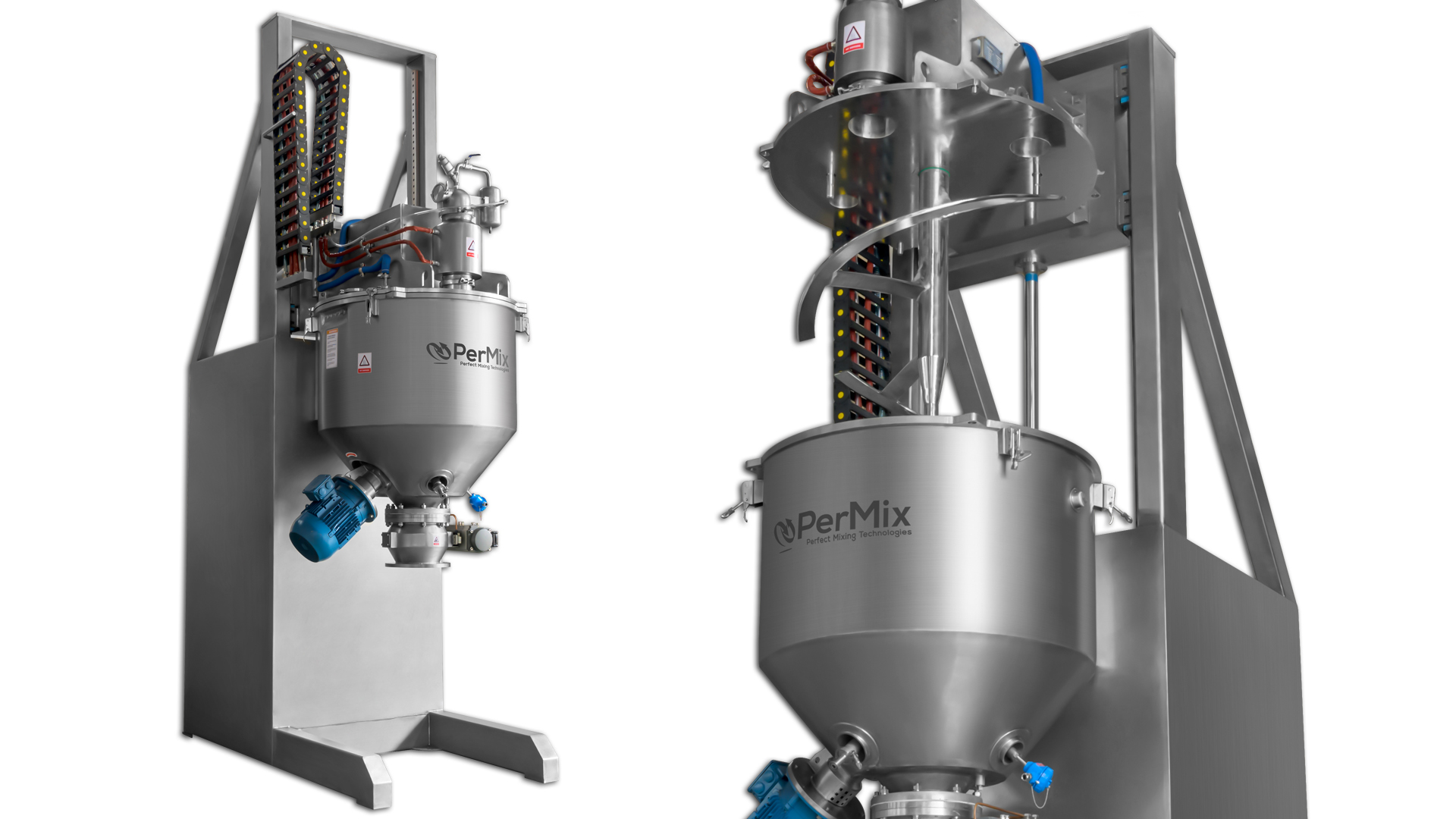

Here is PerMix’s Vertical Vacuum Ribbon Mixer/Dryer. This was custom engineered for high-temperature vacuum mixing & drying in explosive & hazardous atmospheres. The custom-engineered ribbon mixer was designed to handle temperatures up to 300•C while under full vacuum. It was designed to blend and mix metal powders for 3D printing.

Come see the PerMix difference at www.permixmixers.com or www.permixmixers.mx

#permix#ribbonmixers#innovation#engineering#chemicalmanufacturing#pharmaceuticalmanufacturing#foodmanufacturing#mixers#mixing#powdermixing#powdermixer