Vacuum Emulsifiers: An All-In-One Mixer With Versatility

Vacuum Emulsifiers: Advantages Of Using An All-In-One Machine

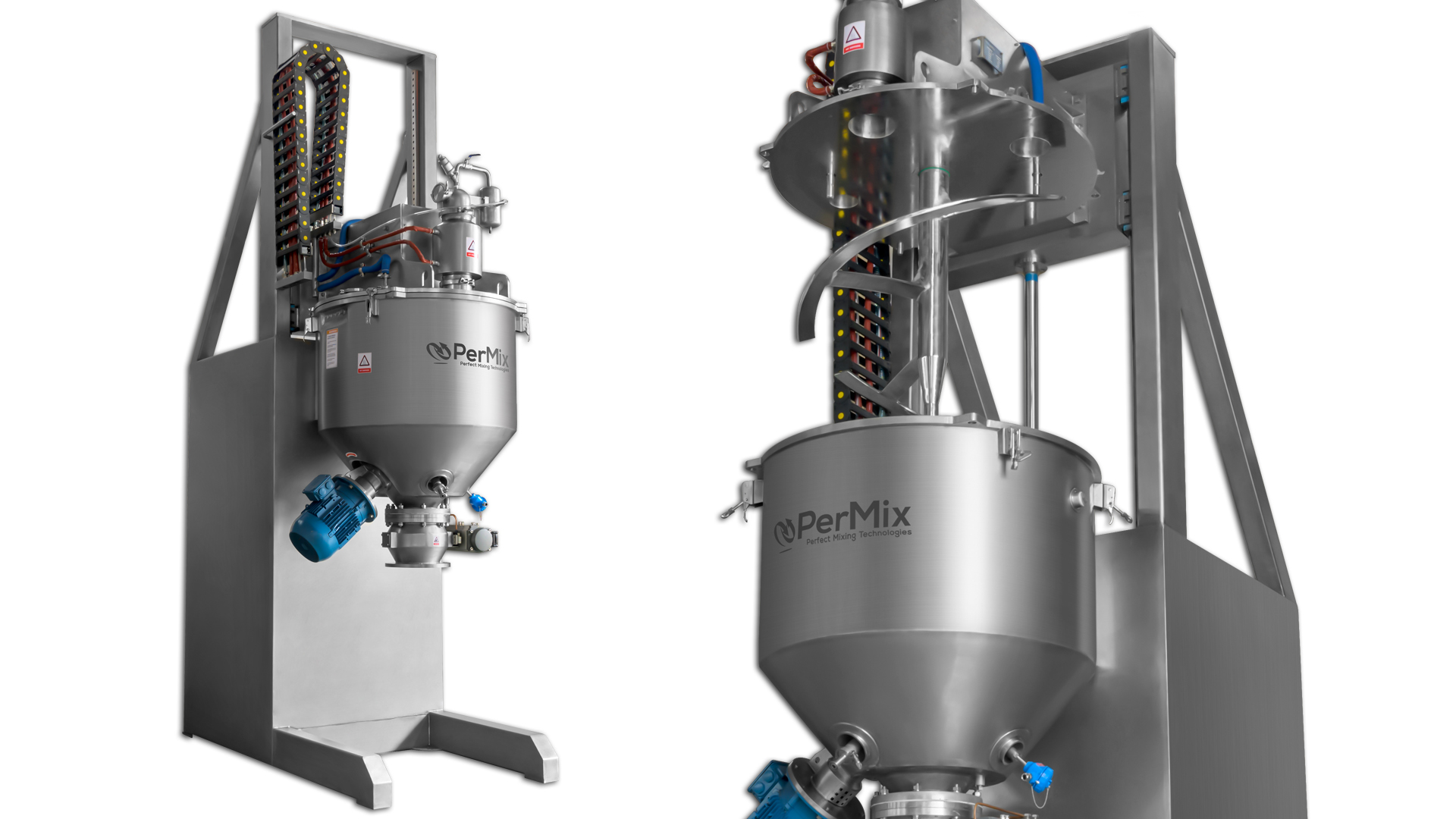

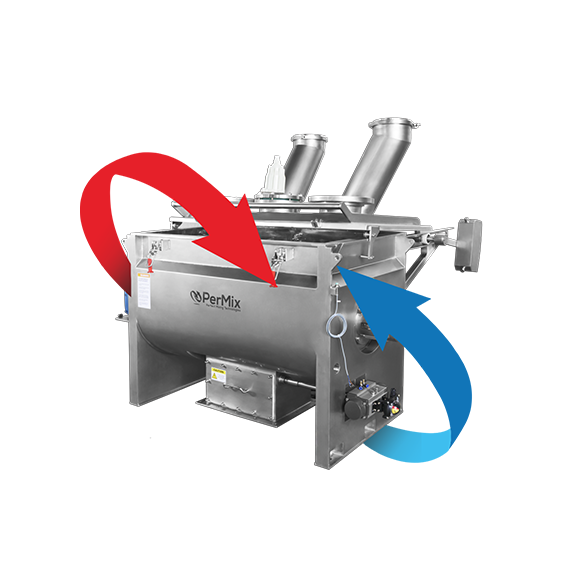

Vacuum emulsifiers are machines that combine mechanical, thermal and chemical processes to create emulsions, a process known as emulsification. They are widely used in the food industry to produce sauces, dressings, and other products, as well as in the cosmetics industry to make creams, lotions, and more. Vacuum emulsifiers offer a number of advantages that make them ideal for these types of applications.

Vacuum emulsifiers are versatile. They can be used to create a variety of different emulsions, from simple oil-in-water emulsions to more complex multiple-phase emulsions. This versatility makes them suitable for a range of different applications.

Vacuum emulsifiers are efficient. They are designed to produce high-quality emulsions in a short amount of time. This makes them ideal for high-volume production, as they can quickly process large amounts of product.

Vacuum emulsifiers are easy to use. They can be operated with minimal training and require minimal maintenance. This makes them ideal for small businesses, as they are easy to set up and use.

Vacuum emulsifiers are cost-effective. They are relatively inexpensive, and their low cost makes them attractive to businesses looking to save money.

Vacuum emulsifiers are safe. They use a low-temperature process, so they are less likely to damage delicate ingredients. Furthermore, they are equipped with safety features to protect the operator, making them a safe and reliable choice.

Vacuum emulsifiers are energy-efficient. They use less energy than traditional emulsification processes, making them an environmentally friendly option.

Vacuum emulsifiers are reliable. They are designed to produce consistent results each time, ensuring that the product meets the desired quality standards.

Overall, vacuum emulsifiers are a great choice for businesses looking for a reliable, cost-effective, and efficient way to produce emulsions. They offer a number of advantages that make them an ideal choice for a range of applications. If you are looking for an all-in-one machine for emulsification, vacuum emulsifiers are definitely worth considering.