The Role of Sigma Mixers in Silicone and Adhesive Manufacturing

The Role of Sigma Mixers in Silicone and Adhesive Manufacturing

Introduction: Silicones and adhesives are integral components in various industries, finding applications in sectors ranging from electronics to construction. The production of these versatile materials involves intricate processes, and sigma mixers play a crucial role in ensuring the quality and consistency of the final products.

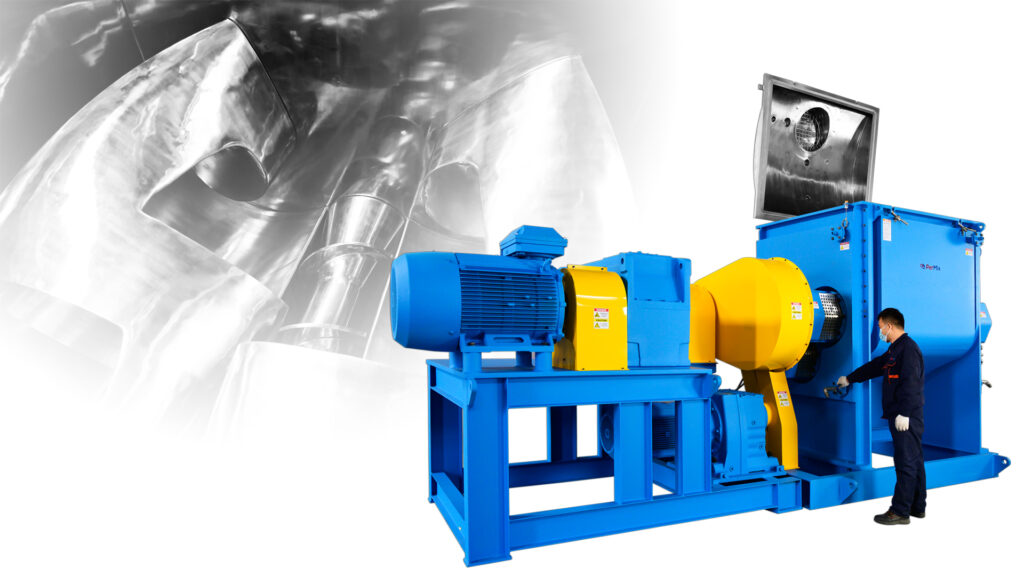

Sigma Mixers: An Overview: Sigma mixers, also known as double-arm mixers, are industrial mixing machines designed for the efficient blending of high-viscosity materials. These robust machines feature two counter-rotating blades, resembling the Greek letter sigma, which work in tandem to knead and mix raw materials. The unique design of sigma mixers makes them ideal for handling dense and sticky substances, making them indispensable in the manufacturing of silicones and adhesives.

Silicone Manufacturing with Sigma Mixers: Silicones, known for their heat resistance, flexibility, and excellent electrical insulation properties, are synthesized using a combination of silicone polymers, reinforcing fillers, and catalysts. The sigma mixer facilitates the homogenous blending of these ingredients, ensuring uniform distribution and optimal cross-linking during the curing process.

- Weighing and Dispensing: The raw materials, including silicone polymers, fillers, and catalysts, are precisely weighed and dispensed into the sigma mixer.

- Mixing and Kneading: The sigma mixer’s dual blades work to knead and mix the ingredients thoroughly. This process promotes the even distribution of fillers and catalysts throughout the silicone polymer matrix.

- Heating and Curing: After achieving a consistent blend, the mixture is transferred to a curing process, often involving heat. The sigma mixer’s contribution ensures that the curing agents are uniformly distributed, leading to a high-quality silicone product.

Adhesive Production with Sigma Mixers: Adhesives, used for bonding various materials together, require precise mixing to achieve the necessary bonding properties. Sigma mixers play a key role in the production of adhesives by ensuring thorough dispersion of adhesive components.

- Ingredient Incorporation: Adhesive formulations typically include resins, solvents, and additives. Sigma mixers are employed to effectively incorporate these ingredients into a homogenous mixture.

- Viscosity Control: The counter-rotating blades of the sigma mixer provide intense shear forces, aiding in the control of the adhesive’s viscosity. This is crucial for ensuring the adhesive’s suitability for specific applications.

- Uniformity and Stability: The sigma mixer’s ability to impart consistent mechanical energy to the adhesive mixture results in a stable and uniform product, crucial for achieving reliable bonding performance.

Conclusion: In the production of silicones and adhesives, PerMix sigma mixers serve as indispensable tools, ensuring the uniform blending of raw materials and the creation of high-quality end products. Their role in achieving homogeneity, viscosity control, and stability underscores their importance in the intricate processes of silicone and adhesive manufacturing. As industries continue to demand materials with superior properties, the partnership between sigma mixers and these key components remains essential for meeting stringent quality standards.