Sigma Mixers Allow You To Mix,Blend, Knead, & Form All In One

PerMix Sigma Mixers & Extruders Lead The Industry In Innovation & Performance

The PerMix Sigma Mixers, which is also known as the Double ‘Z’ Arm Kneader, is used for the mixing-kneading of materials with very high viscosity (over 500,000 cps).

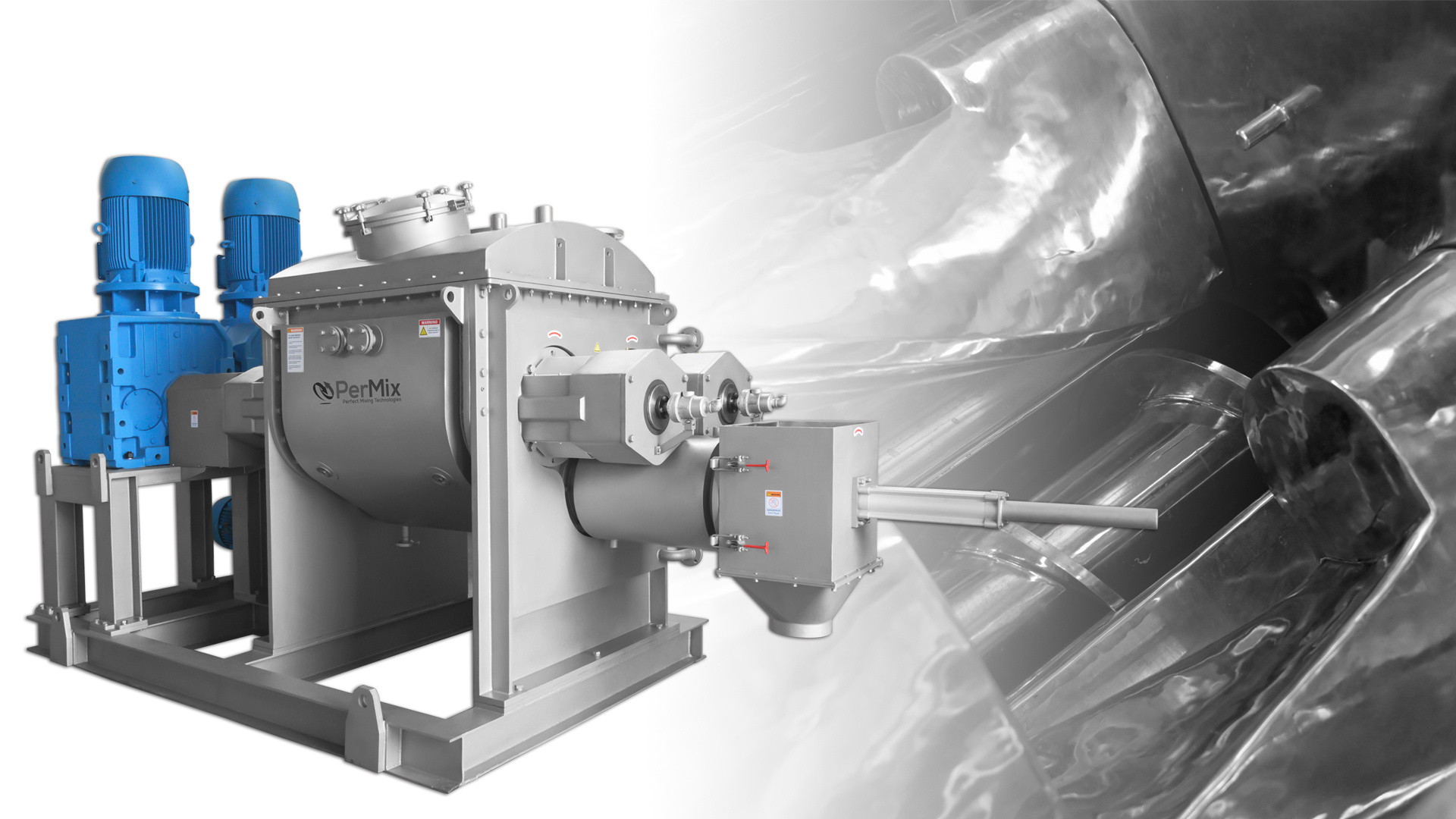

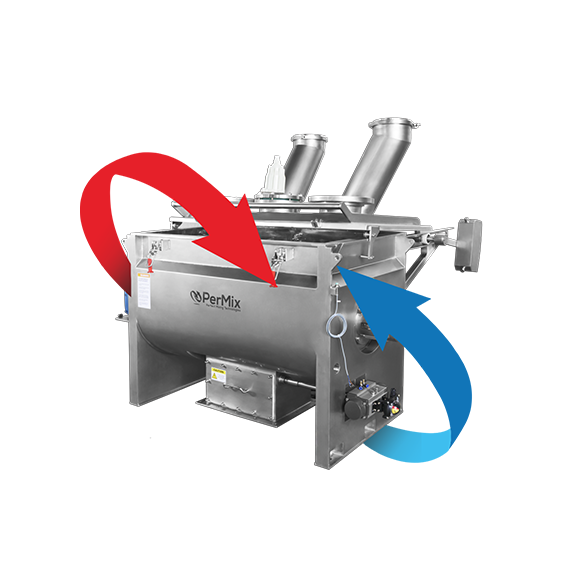

With its unique design of Z-shaped mixing tools installed in two semi-cylinders, the PerMix PSG series Sigma Mixers are able to provide combined functions of compressing, stretching, folding, kneading & mixing, which makes it widely used in the chemical, food, sealing compound and paint industries, among others.

The extrusion-discharge screw is located in the saddle section and runs in a cylindrical trough tangential to, and below the 2 mixing blades. During the mixing cycle, the screw moves the material within the reach of the mixing blades, thus assuring a thorough blending of all the ingredients, and, at the same time, accelerating the mixing process. At discharge time, the direction of rotation of the screw is reversed and the mixed material is extruded through suitable die openings in the side of the machine. The extrusion screw has its own separate drive so that blades and screw operate independently.

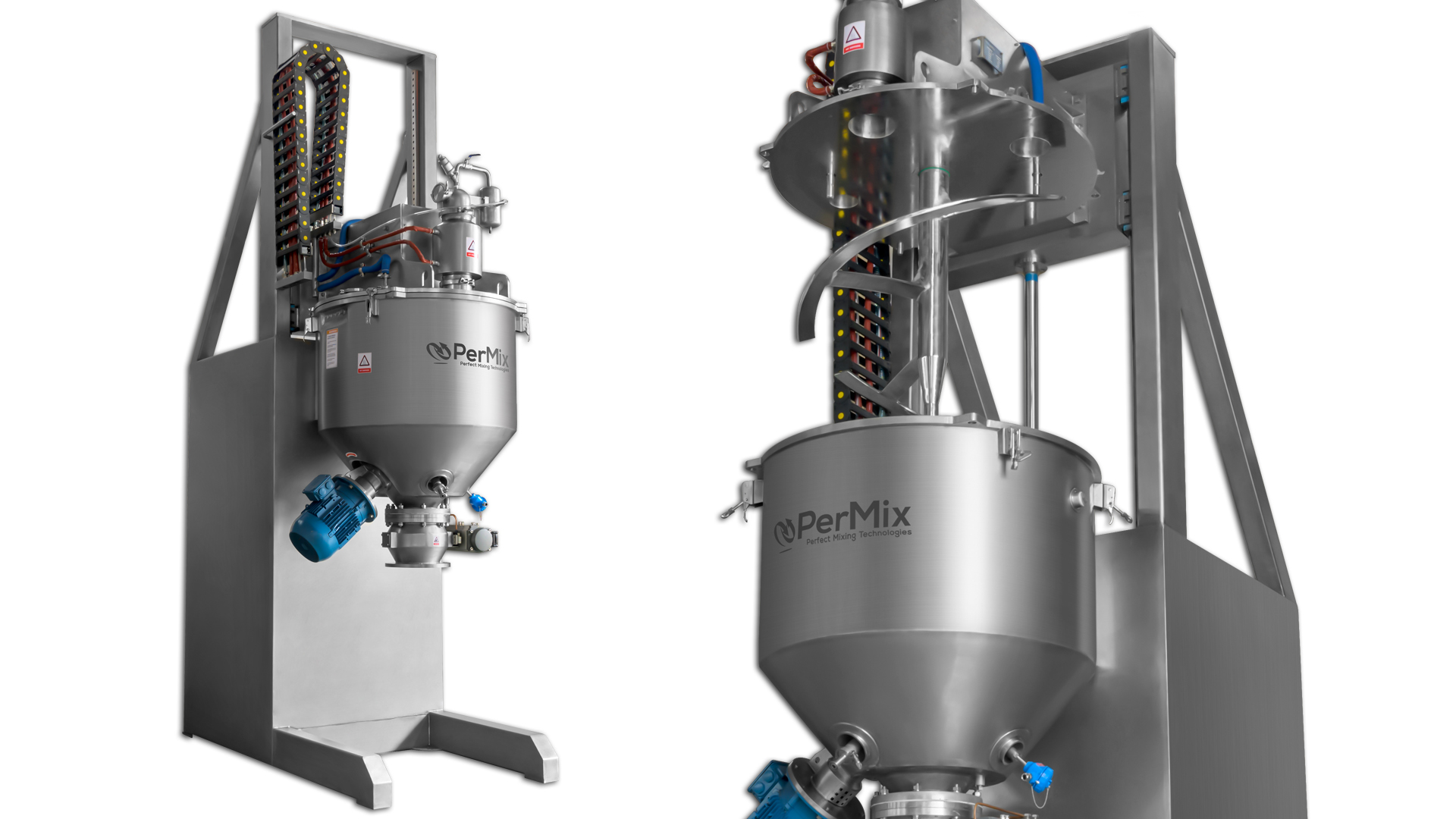

This PerMix PSGX 150, with total volume of 150 lit ( working volume ~ 90 lit ) delivered for a special Polymers manufacturer customer, was supplied with the following features: Vacuum, Double jacket for heating/cooling and more…

Come see the PerMix difference.

#mixing #kneading #permix #sigmamixers #extruders #foodmanufacturing #pharmaceuticalmanufacturing #chemicalmanufacturing #mixers #mixing