Powder Mixers: Using Steam In Agglomeration Of Powders

Powder Mixers: Using Steam In Agglomeration Of Powders, An Efficient & Easy Way To Form Agglomerations

Steam agglomeration is a process in which steam is used to stick together small particles of powder, creating larger agglomerates that can be handled and used more easily. This process has been used in a variety of industries, from food processing to pharmaceuticals to chemical production.

Steam agglomeration is a relatively simple process that can be done at a low cost. Steam is injected into the powder, causing the particles to stick together and form larger agglomerates. The agglomerates are then cooled, dried, and sieved to produce the desired size particles.

Advantages of Steam Agglomeration

Steam agglomeration has a number of advantages over other agglomeration processes. Firstly, it is a low-cost process that does not require expensive equipment. Secondly, it is a relatively quick process, allowing for large quantities of material to be processed in a short period of time. Finally, steam agglomeration is a gentle process that does not damage the particles, allowing for the production of high-quality agglomerates.

Applications of Steam Agglomeration

Steam agglomeration has a number of applications, ranging from food production to pharmaceuticals to chemical production. In the food industry, steam agglomeration is used to produce instant breakfast cereals, instant soups, and other instant food products. In the pharmaceutical industry, it is used to produce tablets and capsules. In the chemical industry, it is used to produce catalysts and other chemicals.

Steam Agglomeration Process

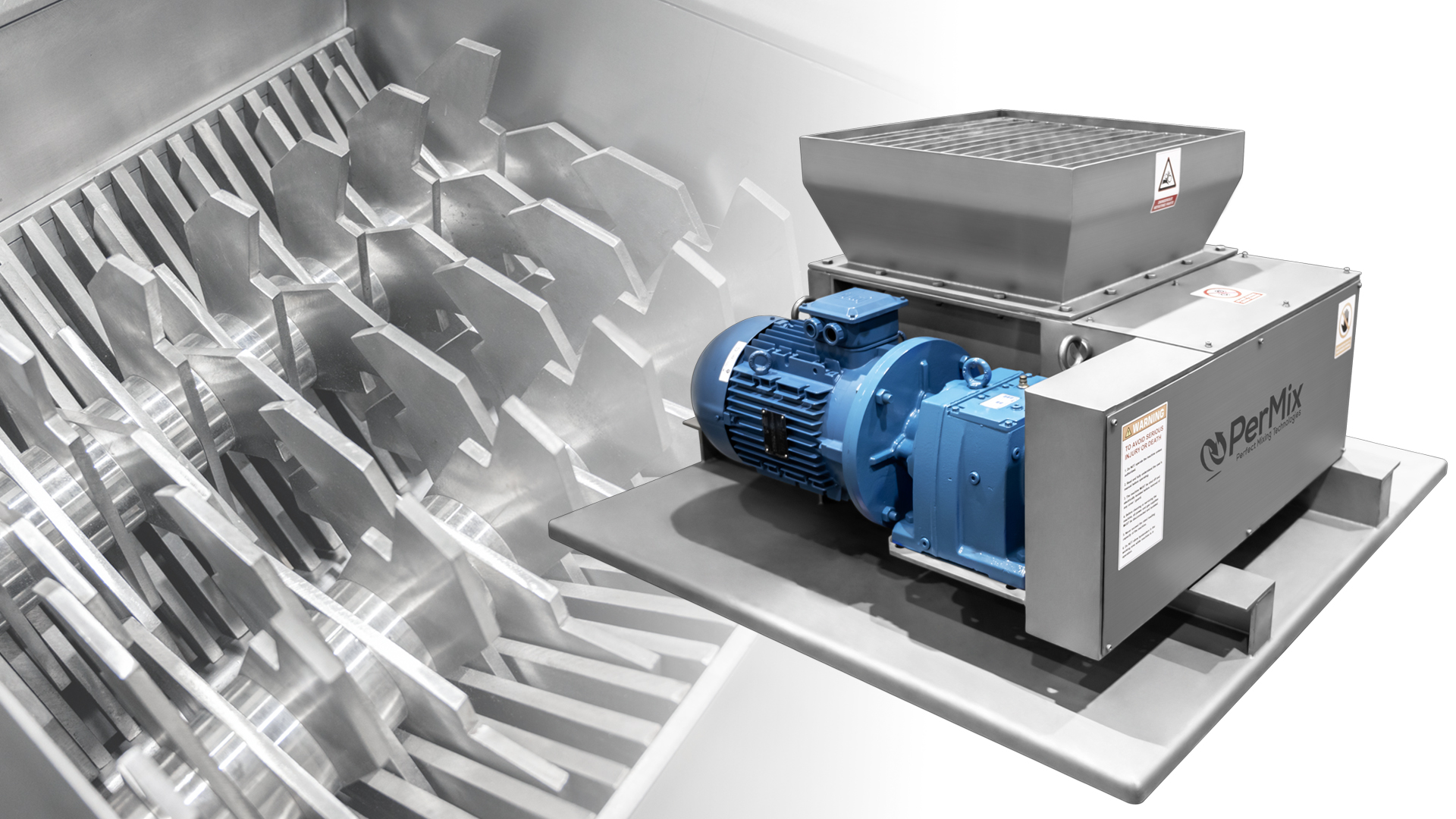

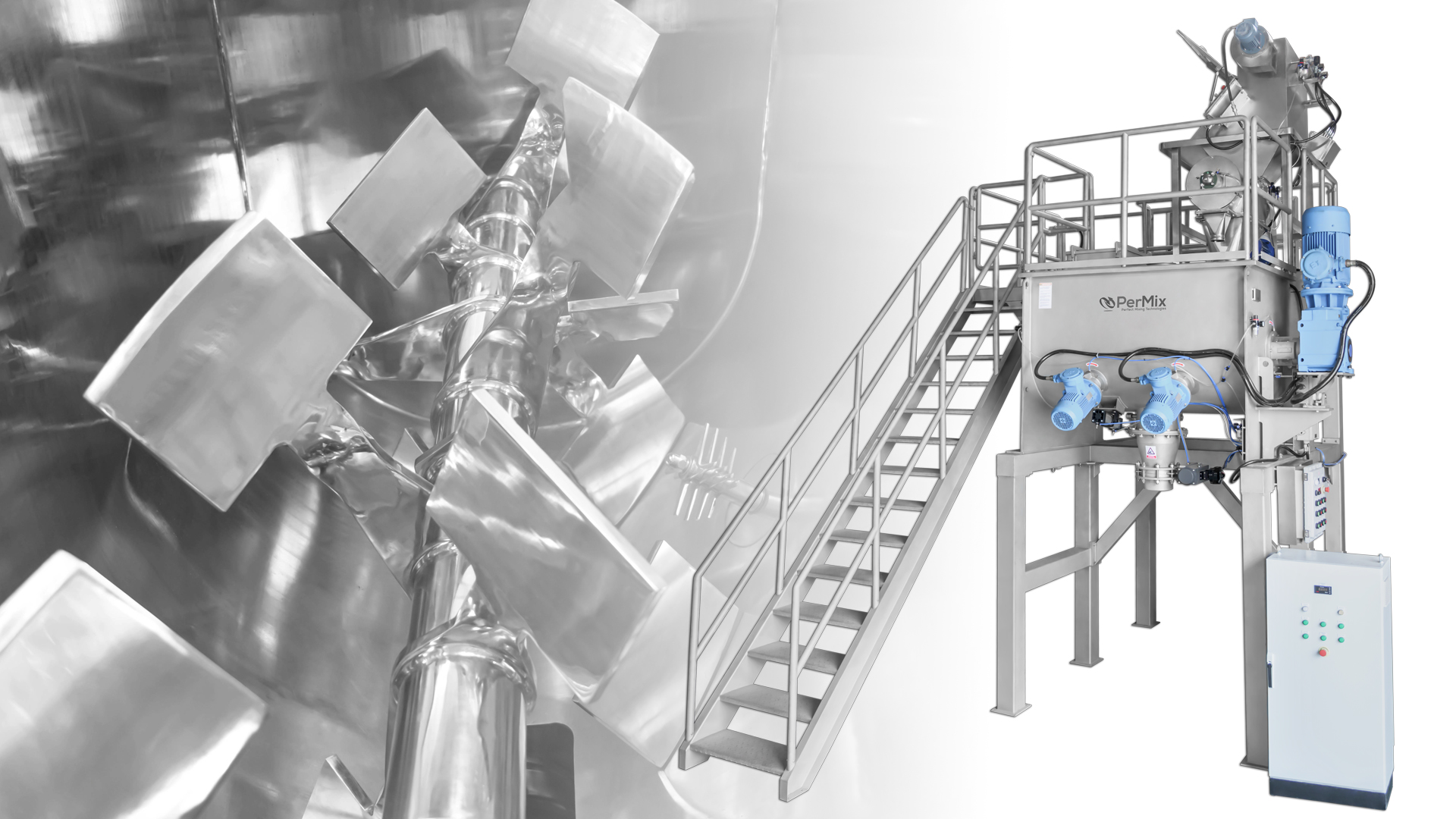

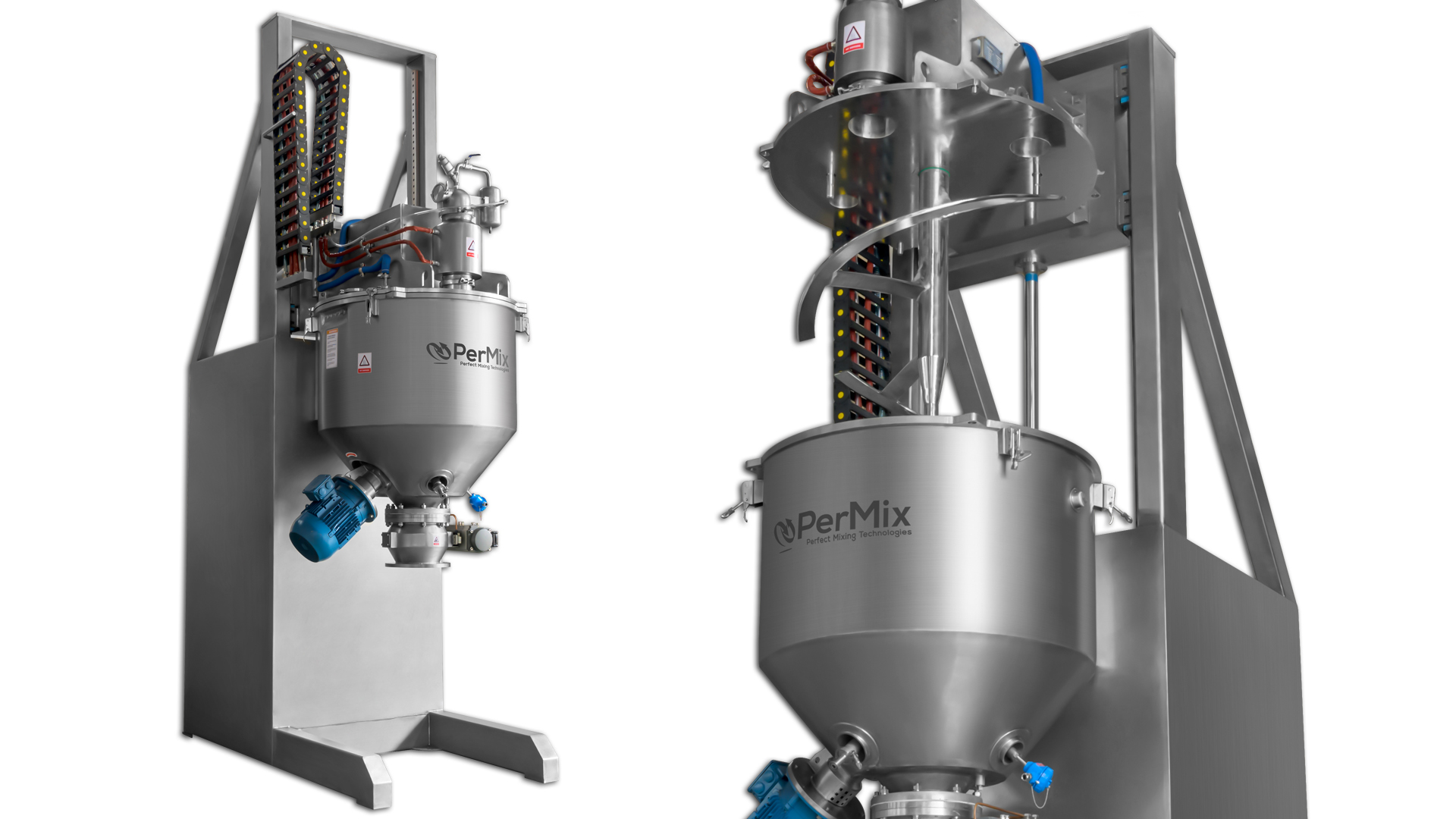

The steam agglomeration process is relatively simple and consists of four steps. Firstly, the powder is fed into the powder mixer or agglomerator, which is a mixing vessel that contains a steam nozzle. The steam is injected into the powder, causing the particles to stick together and form agglomerates. The agglomerates are then cooled, dried, and sieved to produce the desired size particles. Finally, the agglomerates are collected and packaged.

Conclusion

Steam agglomeration is a simple and cost-effective process that is used to agglomerate powders for a variety of applications. It has a number of advantages over other agglomeration processes, such as low cost and quick processing times. The steam agglomeration process consists of four steps, and can be used to produce a variety of agglomerates for different industries.