Powder Mixers: Shearing Effects Of Mixing On Powders

Powder Mixers & The Shearing Effects Of Mixing On Powders

Mixing is a process used to combine multiple ingredients into a homogenous mixture. It is a common step in many industries, especially in the food and pharmaceutical industries. The purpose of mixing is to evenly disperse the ingredients, create a homogenous mixture, and achieve desired physical and chemical properties. In many cases, the mixture must be maintained at a constant temperature to ensure proper mixing and homogeneity.

Mixing of powders is a complex process due to the influence of several external factors such as temperature, particle size, and surface area. One of the most important factors influencing the mixing of powders is the shearing effect. Shear forces are generated when particles move against each other, causing them to break apart and form smaller particles. This process can occur in multiple ways, including mechanical mixing, high intensity mixing, and wet mixing.

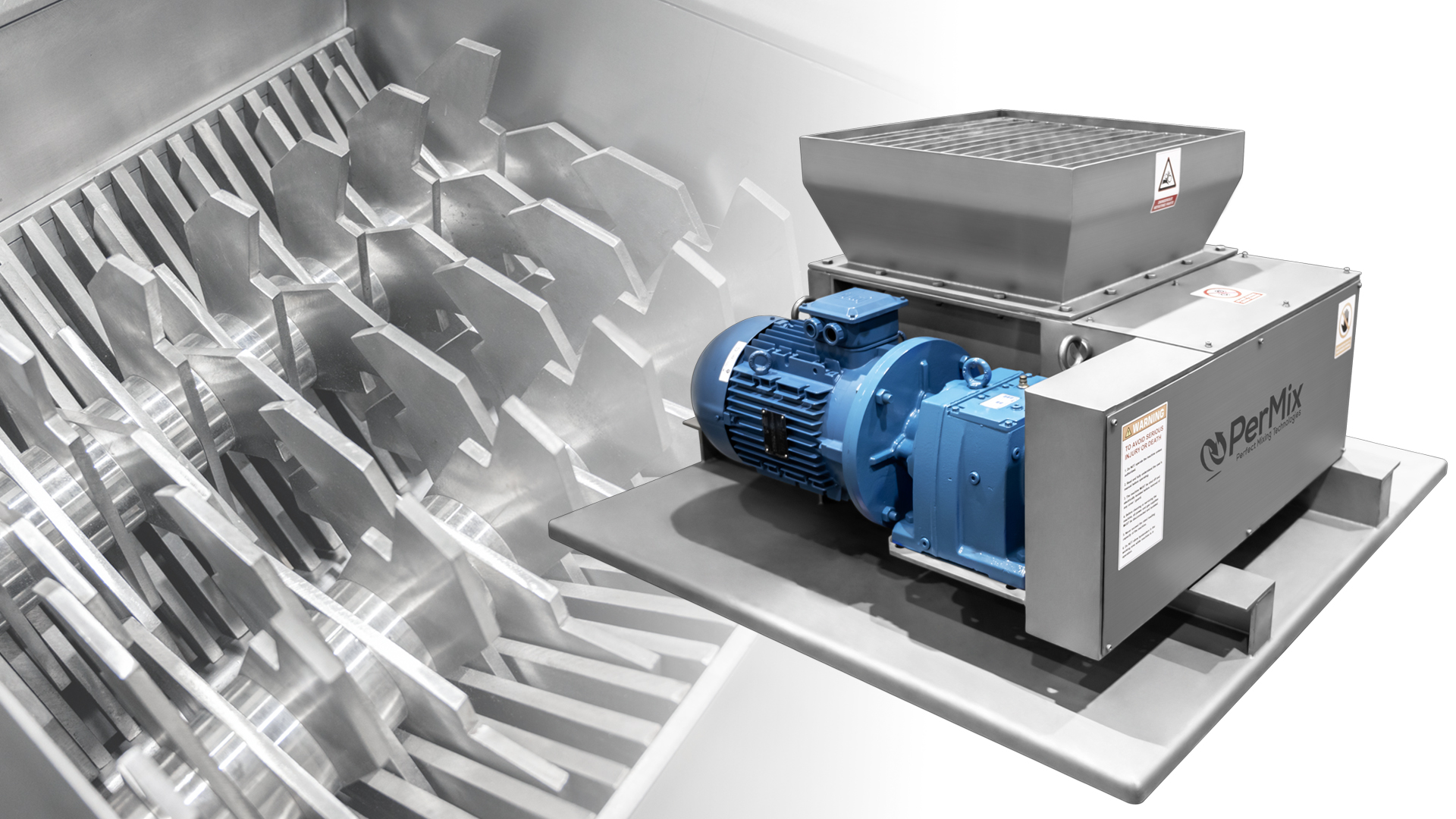

Mechanical Mixing

Mechanical mixing is the most common mixing process used to mix powders. It involves the use of a mechanical device such as a blender, a mixer, or a stirrer to agitate the powder particles and cause them to break apart. The shearing effect of mechanical mixing is limited due to the low intensity of the forces generated by the device.

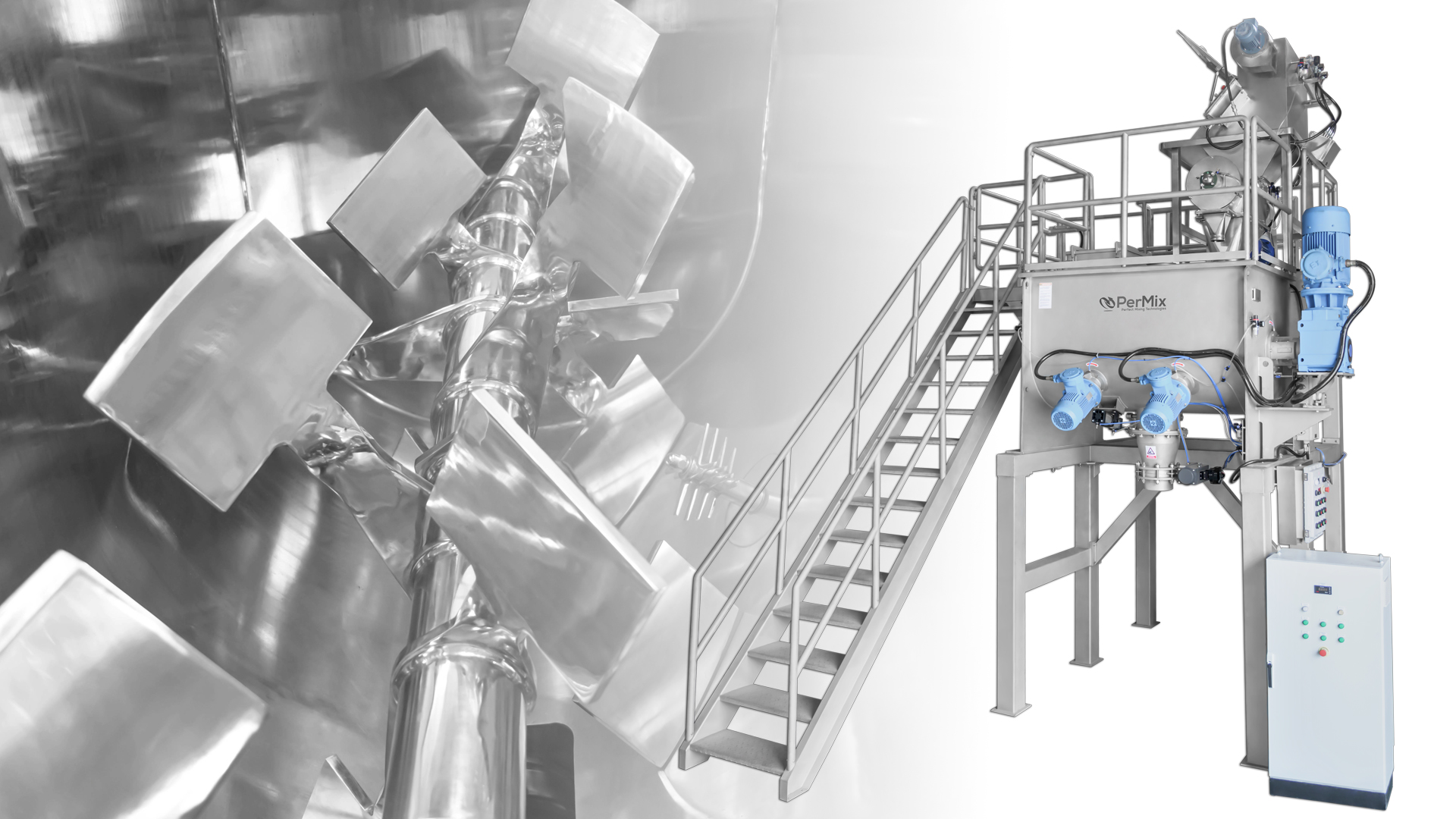

High Intensity Mixing

High intensity mixing is a process that uses high-energy machines to mix powders. These machines generate intense shearing forces that are able to break apart particles much more efficiently than mechanical mixing. This process is often used in the pharmaceutical industry to ensure homogenous mixtures and to achieve desired properties in the final product.

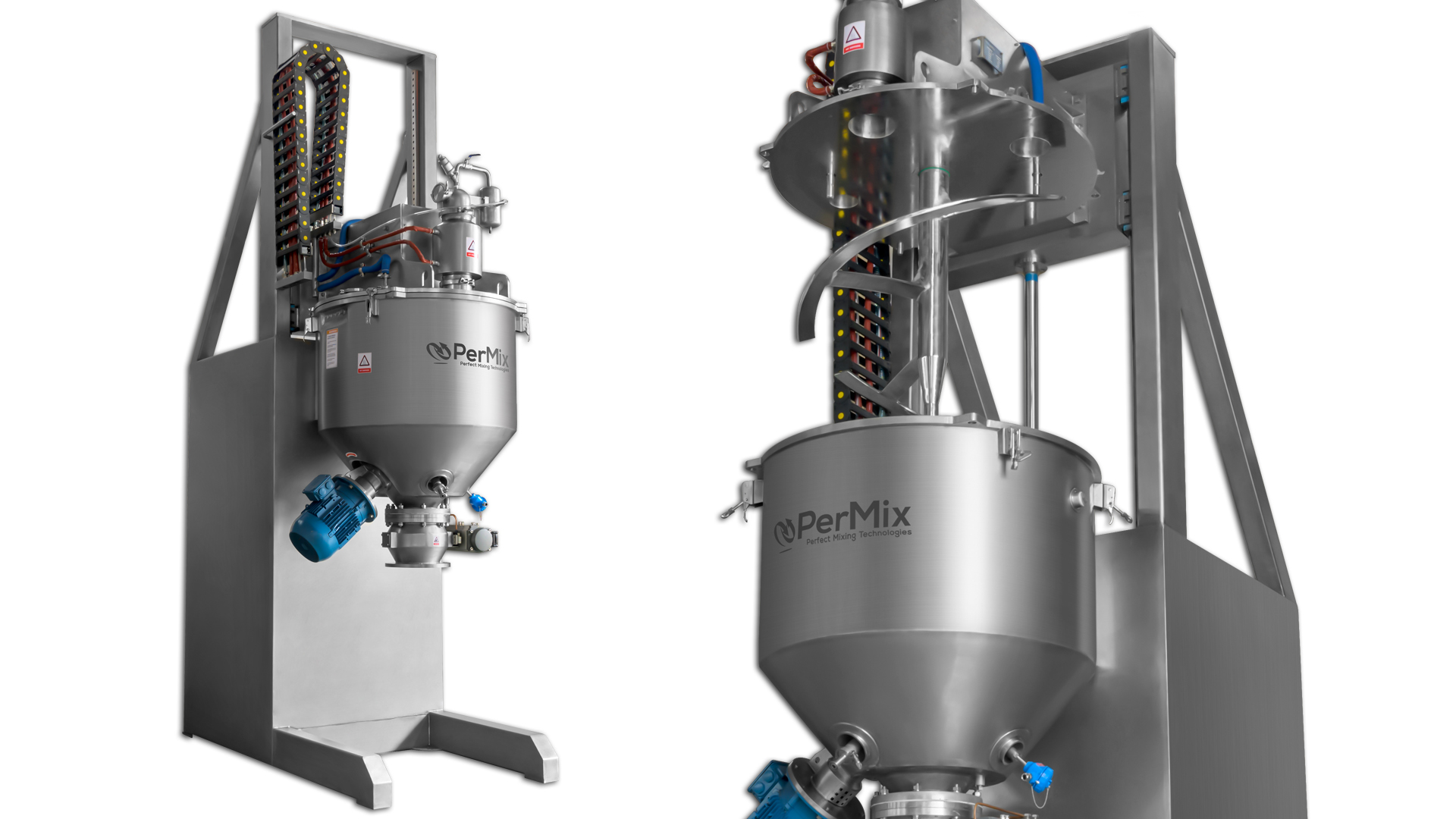

Wet Mixing

Wet mixing is a process that involves adding a liquid to the powder mixture in order to increase the shearing effect. This process is often used in the food industry to homogenize mixtures and to improve the texture and appearance of the final product. The shearing effect of wet mixing is greater than that of mechanical mixing or high intensity mixing due to the increased viscosity of the liquid.

Conclusion

The shearing effect of mixing is an important factor in the homogenization of powder mixtures. Different methods of mixing can be used to achieve different results, depending on the desired outcome. Mechanical mixing is the most common method of mixing, but it is limited in its ability to break apart particles. High intensity mixing and wet mixing are more effective in breaking down particles and improving the homogeneity of the mixture.