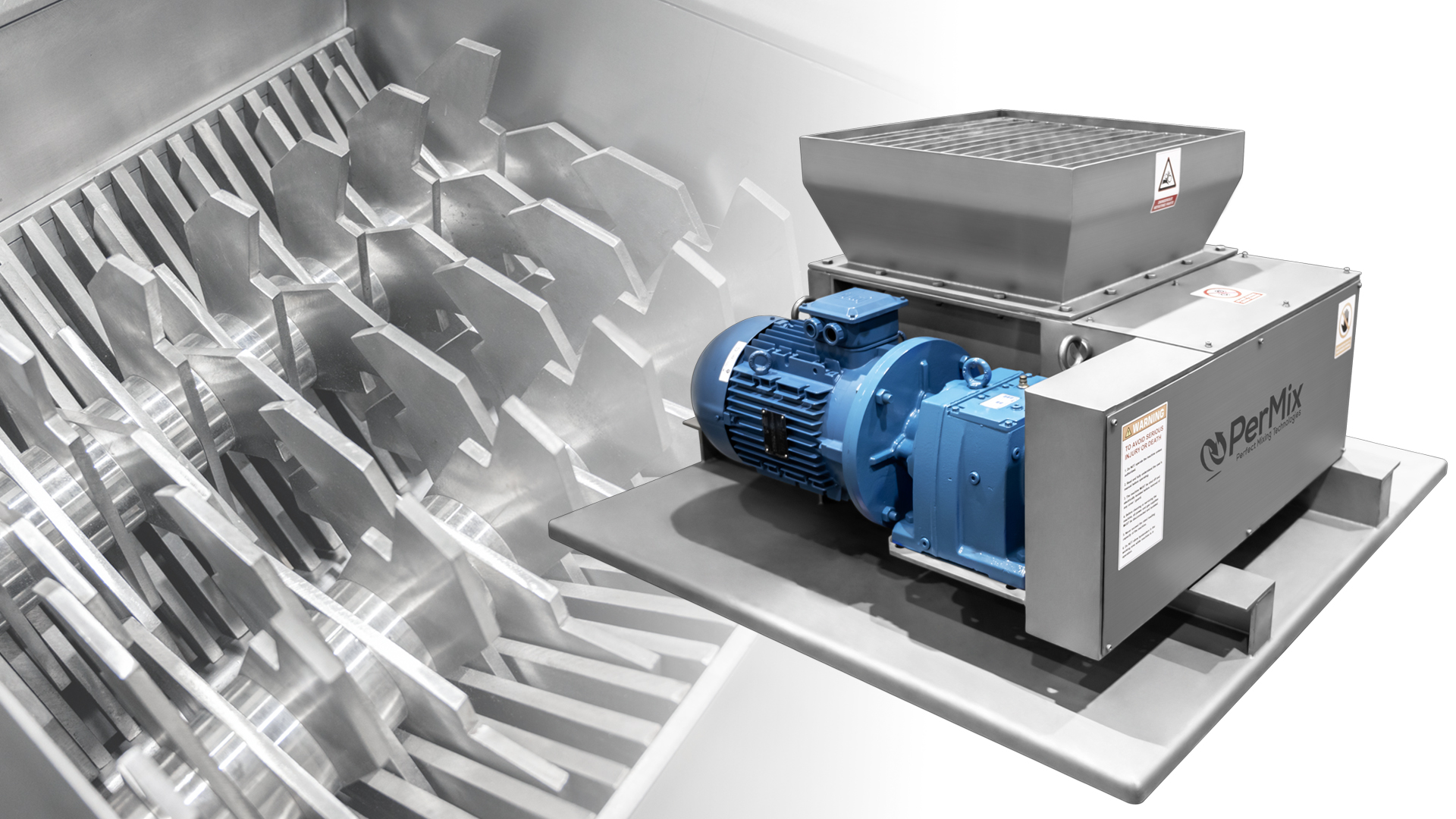

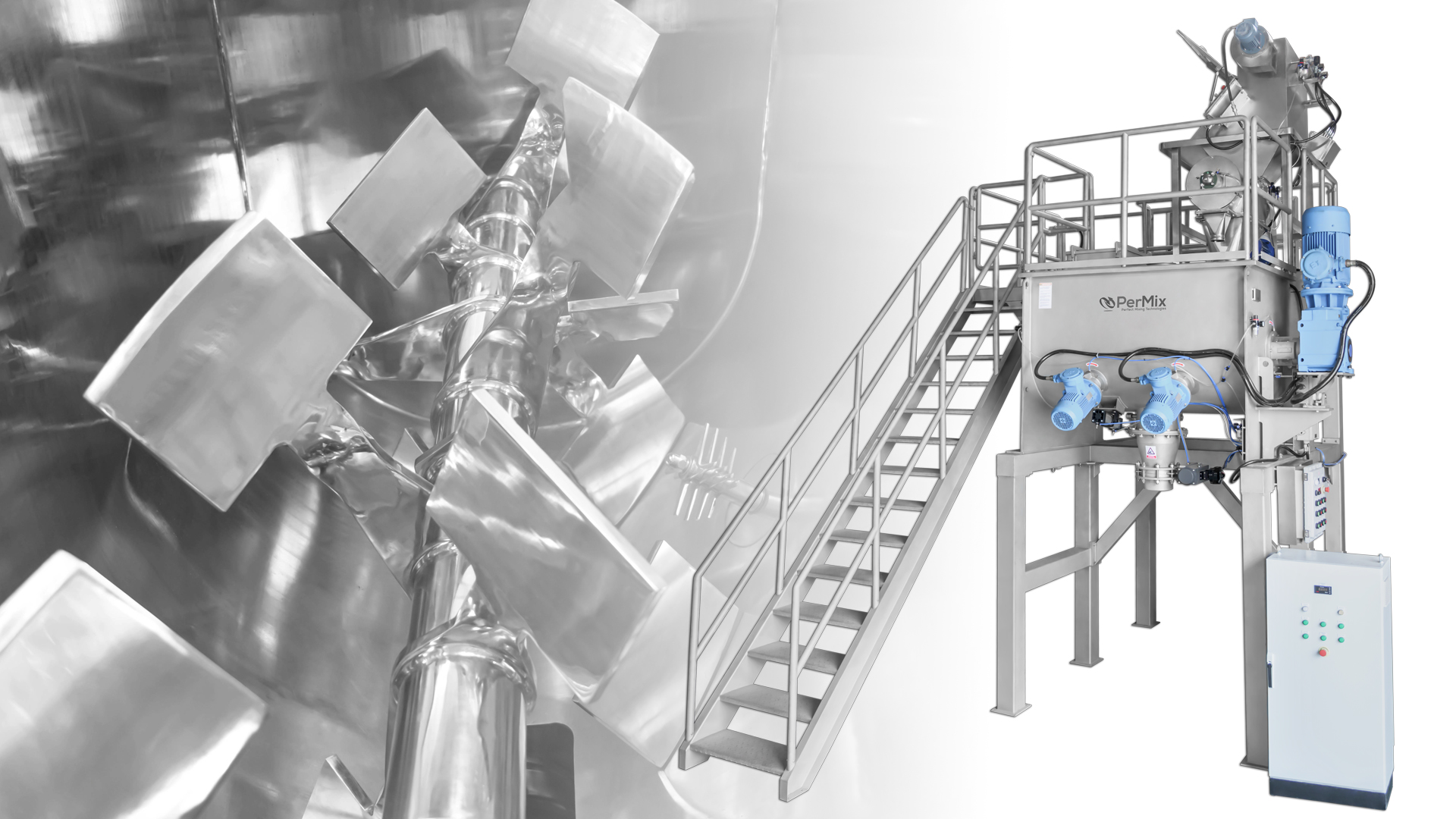

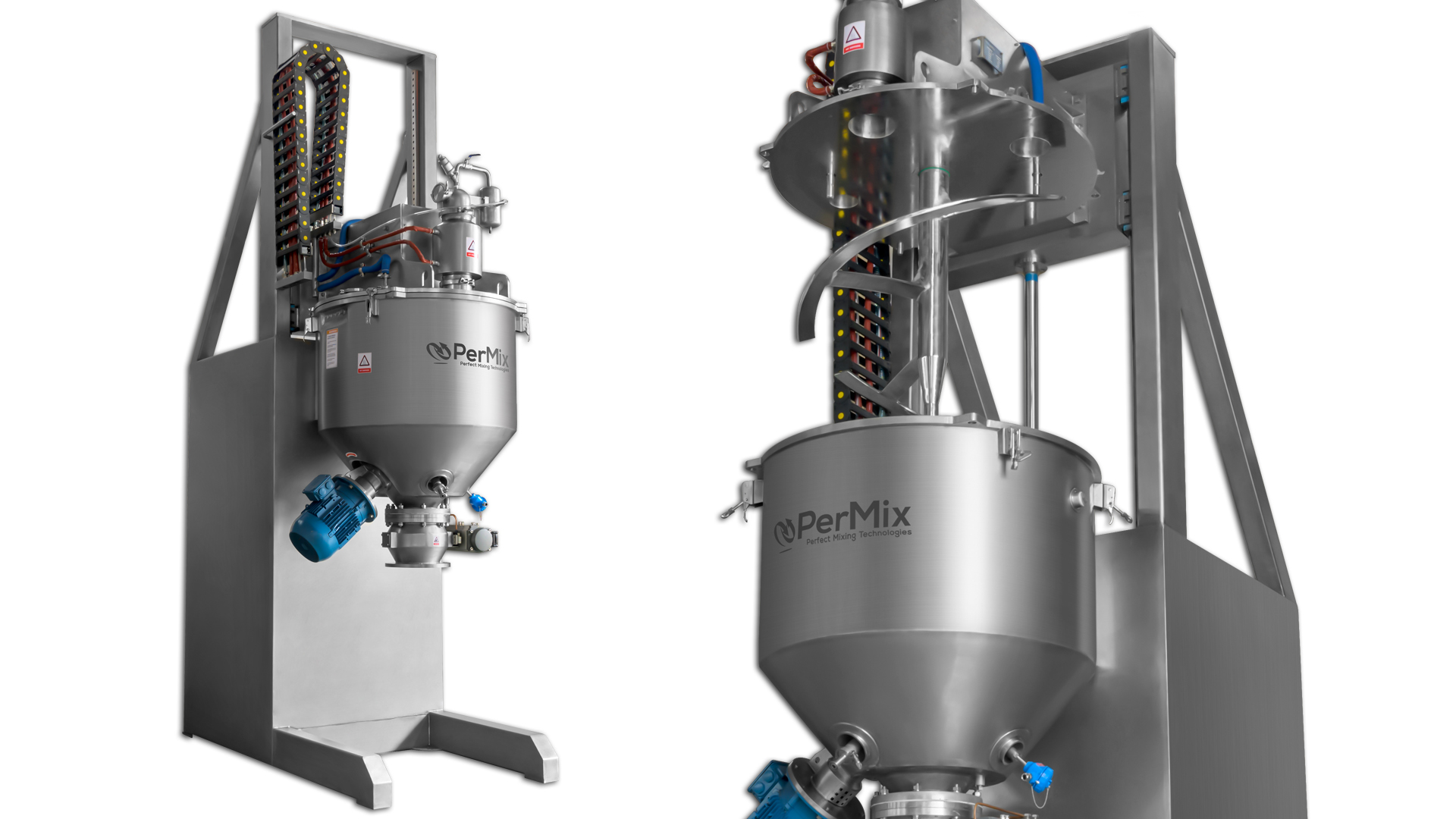

Powder Mixers For Mixing Abrasives That Last Years

Powder Mixers Built With Hardox Steel For Mixing Abrasives

Mixing abrasives is a vital part of many industrial processes. Whether it is for the manufacturing of many products or for the maintenance and repair of industrial machinery, the correct mixing of abrasives is essential. In order to ensure the correct mixing of abrasives, the right materials must be used. One such material is Hardox coated stainless steel.

What is Hardox?

Hardox is a type of abrasion-resistant steel developed by SSAB, a Swedish steel manufacturer. It is a highly durable material that is resistant to wear and tear, making it ideal for applications where abrasive materials are used. Hardox is also highly impact-resistant, meaning it can withstand the pressures created by the mixing of abrasives.

What are the advantages of using Hardox for mixing abrasives?

The main advantage of using Hardox for mixing abrasives is its durability and resistance to wear and tear. As abrasive materials are often highly abrasive, they can easily wear down other materials. However, Hardox is highly resistant to this kind of wear and tear, meaning it can be used for a longer period of time without requiring replacement.

Another advantage of using Hardox for mixing abrasives is that it is highly impact-resistant. Mixing of abrasives often involves high pressures and impacts, which can cause damage to other materials. However, Hardox is highly resistant to these kinds of impacts, meaning it can be used for mixing abrasives without fear of damage.

Finally, Hardox is also a highly corrosion-resistant material. As abrasive materials often contain corrosive agents, the mixing of abrasives can lead to corrosion of other materials. However, Hardox is highly resistant to corrosion, meaning it can be used for mixing abrasives without fear of corrosion.

What are the disadvantages of using Hardox for mixing abrasives?

Despite its many advantages, Hardox does have some drawbacks when it comes to using it for mixing abrasives. Firstly, Hardox is a relatively expensive material, meaning it may not be the most cost-effective solution for all applications.

Another disadvantage of using Hardox for mixing abrasives is that it is a relatively heavy material. This means that it is not suitable for all applications, particularly those where portability is important.

Finally, Hardox is not a very flexible material, meaning it may not be suitable for applications where flexibility is required.

Conclusion

In conclusion, Hardox coated stainless steel is an ideal material for mixing abrasives. It is highly durable and resistant to wear and tear, making it ideal for applications where abrasive materials are used. It is also highly impact-resistant and corrosion-resistant, meaning it can be used for a longer period of time without fear of damage or corrosion. However, it is an expensive material and is not very flexible, meaning it may not be suitable for all applications.

Overall, Hardox coated stainless steel is an excellent choice for mixing abrasives, as long as the application is suitable for its characteristics.

Come see the PerMix difference