PerMix Plow Mixer Vacuum Mixer/Dryer: Unlocking the Future of Nanotechnology

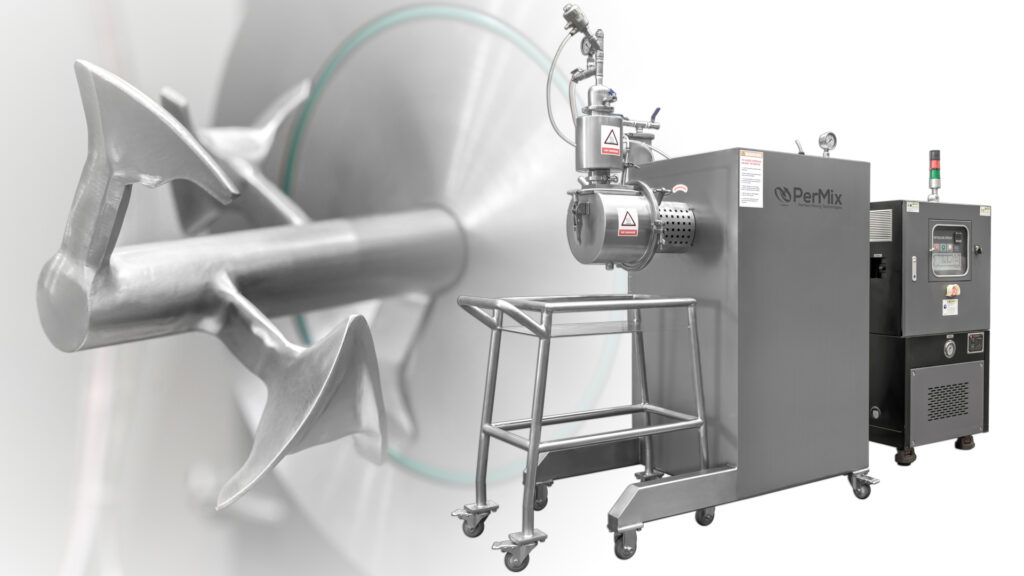

Unlocking the Future of Nanotechnology with the PerMix Plow Mixer Vacuum Mixer/Dryer

In the rapidly advancing field of nanotechnology, the demand for versatile and efficient mixing solutions is more crucial than ever. The PerMix Plow Mixer Vacuum Mixer/Dryer stands out as an essential tool in laboratory and R&D facilities, providing unmatched performance that meets the unique requirements of nanotech applications. With capabilities for extended run times, high temperatures up to 350°C, cryogenic freezing, and gas purging with various types of gases, PerMix is paving the way for innovative breakthroughs.

Achieve Longer Run Times

One of the standout features of the PerMix Plow Mixer is its ability to operate continuously for extended periods. This capability is particularly beneficial in the development of nanomaterials, where consistent mixing is essential for achieving homogeneity and optimal particle distribution. Researchers can conduct lengthy experiments without interruption, ensuring that they can focus on their work rather than equipment downtime.

High-Temperature Processing

Nanotechnology often requires precise control over thermal conditions. The PerMix Plow Mixer Vacuum Mixer/Dryer can reach temperatures of up to 350°C, allowing for effective processing of heat-sensitive materials. This high-temperature capability enables researchers to explore new avenues in material synthesis, polymerization, and other critical processes where traditional mixing equipment might fall short.

Cryogenic Freezing for Unique Applications

In addition to its high-temperature capabilities, the PerMix Plow Mixer can also achieve cryogenic temperatures, providing a unique solution for applications that require rapid cooling or freezing. This is particularly useful in the field of nanotechnology, where controlling particle size and morphology is vital. By combining heating and cryogenic freezing capabilities in one machine, PerMix offers unparalleled flexibility for innovative research and development.

Gas Purging with Versatile Options

To further enhance the capabilities of the PerMix Plow Mixer, it includes a sophisticated gas purging feature. Researchers can utilize various types of gases—such as nitrogen, argon, or carbon dioxide—depending on the specific requirements of their processes. Gas purging is essential for maintaining an inert atmosphere, preventing oxidation, and ensuring the stability of sensitive materials during mixing and drying. This feature allows for precise control of the mixing environment, contributing to improved product quality and consistency.

Engineered for Tomorrow’s Needs

PerMix understands that the challenges faced by researchers today are evolving, and so are the solutions required to meet those challenges. The Plow Mixer Vacuum Mixer/Dryer is designed to adapt to the future needs of the industry, ensuring that your lab is equipped to tackle the next generation of nanotechnology research.

Conclusion

In the pursuit of cutting-edge advancements in nanotechnology, the PerMix Plow Mixer Vacuum Mixer/Dryer is an invaluable asset for any laboratory or R&D facility. Its ability to provide longer run times, high-temperature processing, cryogenic freezing, and gas purging with various gases sets it apart as a leader in the field. Embrace the future of nanotechnology with PerMix and take your research to new heights.

#permix #mixers #mixing #nanotechnology #blending #blenders #gaspurging #pharmaceuticals #pharmaceuticalmanufacturing #foodmanufacturing #chemicalmanufacturing