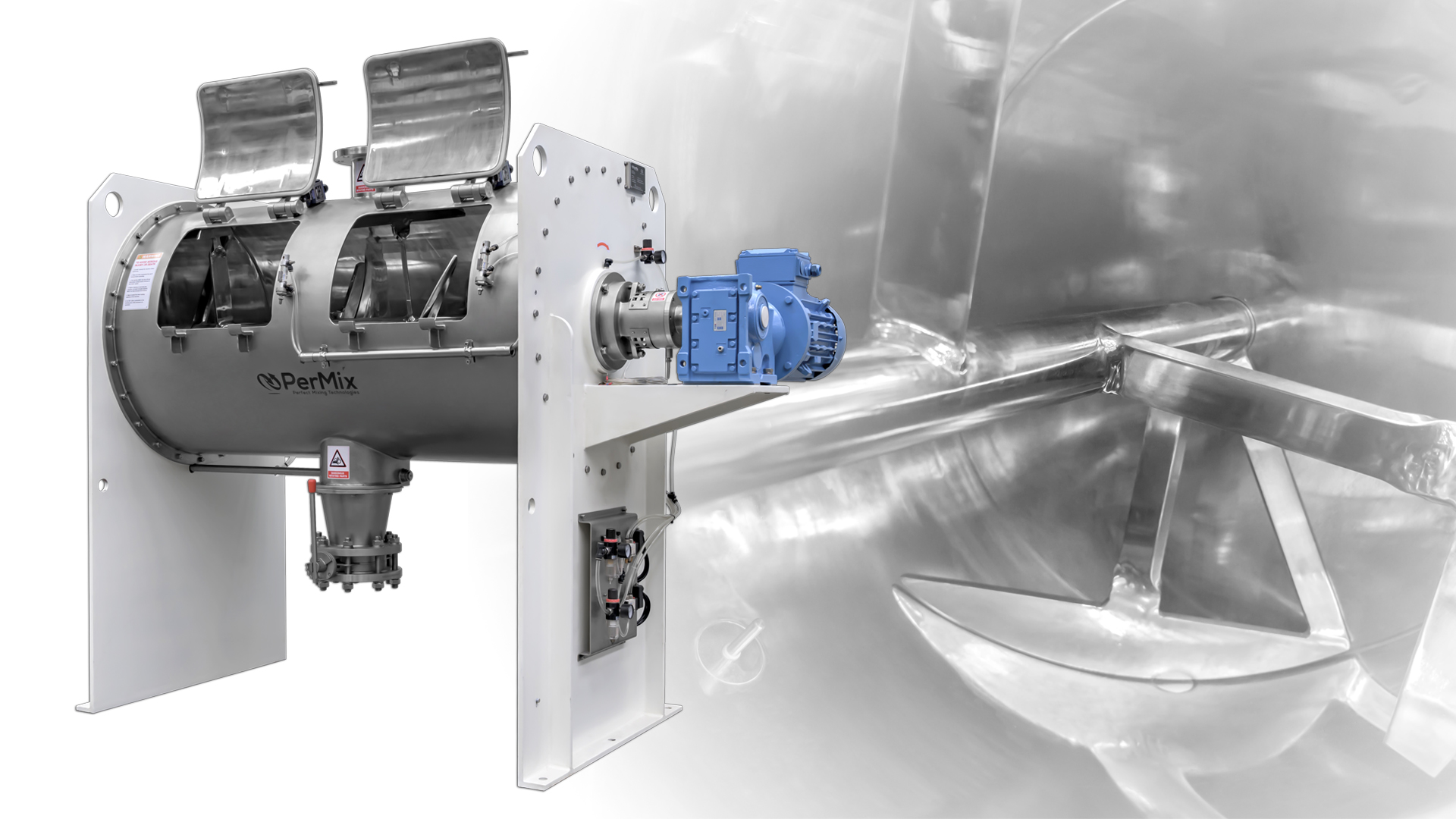

Powder Mixers & The Need For Explosion Proof Options

The mechanical parts of the mixers are all built according to Ex specifications, eliminating the potential for sparks or ignition points of powders that may be airborne in the air. Often times facilities that deal with powders, such as mills, have airborne particles that present an invisible danger. PerMix ensures that motor, starters, relays, and control, everything from top to bottom is Ex rated all while maintaining performance, quality, innovation, & AFFORDABILITY. Our “Transparency in Pricing” policy lists the main unit then all options under which are requested in Ex, as well as the different levels of certifications. From CE to UL & ETL, Ex to ATEX, & ASME, PD, to CRN, we have the certifications needed for each region. Our global presence & teams ensure everything goes smoothly from start to finish.

This commitment to engineering & innovation & the customer’s needs is what makes PerMix THE most disruptive brand in the industry, setting standards others follow.

Come see the PerMix difference.

#engineering#innovation#quality#permix#explosionproof#explosionprotection#mixing#mixers#foodmanufacturing#bulkmaterialhandling