Mixing Powders: Ribbon Mixers vs Paddle Mixers

Efficiency In Mixing: Ribbon Mixers vs Paddle Mixers, Differences & Efficiencies Explained

Mixing is an important process in many industries, from food production to pharmaceuticals. It is used to combine multiple ingredients and form the desired end product. Mixers come in various shapes and sizes, but the two most commonly used types are ribbon mixers and paddle mixers. Both of these mixers have their own set of advantages and disadvantages, so it is important to understand the differences between them in order to make an informed decision about which type of mixer is best for your needs.

Ribbon Mixers

Ribbon mixers are generally have a U shaped trough in regards to shape and feature a horizontal or vertical arrangement of two or more ribbons. These ribbons rotate in opposite directions and create a spiral mixing action that mixes the ingredients together. Ribbon mixers are often used for mixing large batches of materials, as they can mix a large amount of material and are easy to load given the open, U shaped trough with open top.

One of the main advantages of using a ribbon mixer is that it is able to mix materials that have different sizes, shapes, and densities, in large quantities. This makes it ideal for mixing ingredients such as powders, granules, and liquids. Additionally, ribbon mixers are able to mix at low speeds, making them ideal for delicate products that need to be mixed without being damaged.

However, one of the main drawbacks of using a ribbon mixer is that they are not as efficient at mixing smaller batches of materials. Ribbon mixers tend to have dead spots in the mixing chamber, which can lead to uneven mixing and product separation. Additionally, ribbon mixers may require additional scraping or tumbling to ensure a thorough mix. Heat transfer is also an issue if heating of products is needed. The open top as well as the void space between the product and top makes it an inefficient way of heating.

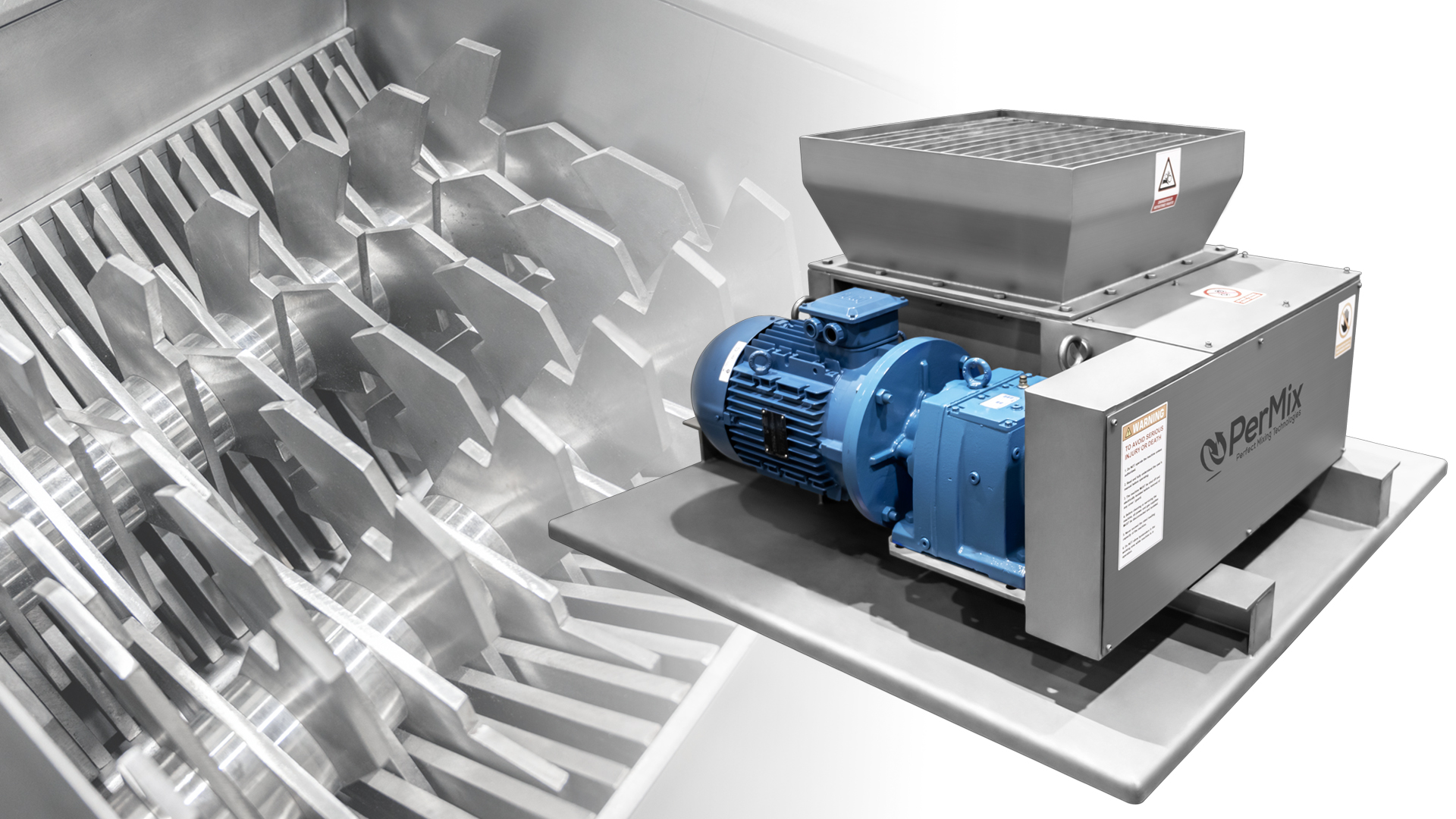

Paddle Mixers

Paddle mixers are generally cylindrical in shape and feature two or more paddles that rotate in the same direction and are staggered. Paddle mixers can create a shearing action if needed, or can be gentle with no shearing, and efficiently mixes the ingredients together in either need. Paddle mixers are often used for mixing smaller batches of materials as well as large batches, as they are able to rapidly mix an amount of material in a short amount of time.

One of the main advantages of using a paddle mixer is that it is able to slowly, delicately, and efficiently mix materials that have different sizes, shapes, and densities. Additionally, paddle mixers are able to mix at high speeds, making them ideal for products that need to be mixed quickly.

Heat transfer is also much better in the paddle mixers as the closed tops and cylindrical design has more surface area, as well as is closed, and increases efficiencies.

However, one of the main drawbacks of using a paddle mixer is that they are not as efficient in loading bulk materials directly into the mixer as the cylinder type configuration typically requires conveying when loading.

Types of Paddle Mixers

• Single Shaft Fluidized Zone Mixer

• Dual Shaft Fluidized Zone Mixer

Conclusion

When choosing a mixer, it is important to consider the size and type of material that needs to be mixed. Ribbon mixers are ideal for mixing large batches of bulk materials when loading without conveyors, while paddle mixers are better suited for mixing small or large batches, but typically require conveying for loading. Additionally, both types of mixers can mix materials with different sizes, shapes, and densities. Ultimately, the decision of which type of mixer is best for your needs will depend on the specific application. In the end, when you compare mixing times and efficiency of batch times, the paddle mixer outperforms the ribbon mixers.