Mixing Graphite Into Concrete, Its Benefits, & How To Mix It

Mixing Graphite Into Concrete And Its Benefits

Mixing Graphite Into Concrete And Its Benefits is a topic that has gained significant attention in recent years. In this blog, we will explore the process of incorporating graphite into concrete and discuss the numerous advantages it offers.

Graphite, a form of carbon, is widely known for its excellent electrical and thermal conductivity properties. When mixed with concrete, it introduces several key benefits that enhance the overall performance and durability of the material.

One of the primary advantages of mixing graphite into concrete is its ability to improve thermal conductivity. Graphite particles act as a conductor, allowing heat to transfer more efficiently through the concrete matrix. This property is particularly beneficial in applications where temperature control is crucial, such as in the construction of industrial buildings or structures exposed to extreme weather conditions.

Furthermore, the incorporation of graphite can greatly enhance the electrical conductivity of concrete. This characteristic makes it an ideal choice for projects that require effective grounding or electromagnetic shielding. By adding graphite, the concrete gains the ability to dissipate electrical charges, reducing the risk of electrical hazards and improving overall safety.

In addition to its conductivity properties, mixing graphite into concrete can also enhance its strength and durability. The presence of graphite particles helps to reduce the formation of microcracks and inhibit the propagation of larger cracks, thereby improving the material’s resistance to mechanical stress and extending its service life.

Moreover, graphite can contribute to the self-lubricating properties of the concrete. The presence of graphite particles reduces friction between the concrete components, allowing for easier movement and reducing the risk of wear and tear. This characteristic is particularly advantageous in applications where frequent movement or sliding occurs, such as in the construction of bridges or road surfaces.

Another notable benefit of incorporating graphite into concrete is its corrosion resistance. Graphite particles act as a barrier, preventing the penetration of corrosive substances into the concrete matrix. This property is especially valuable in structures exposed to harsh environments or in contact with chemicals, such as wastewater treatment plants or industrial facilities.

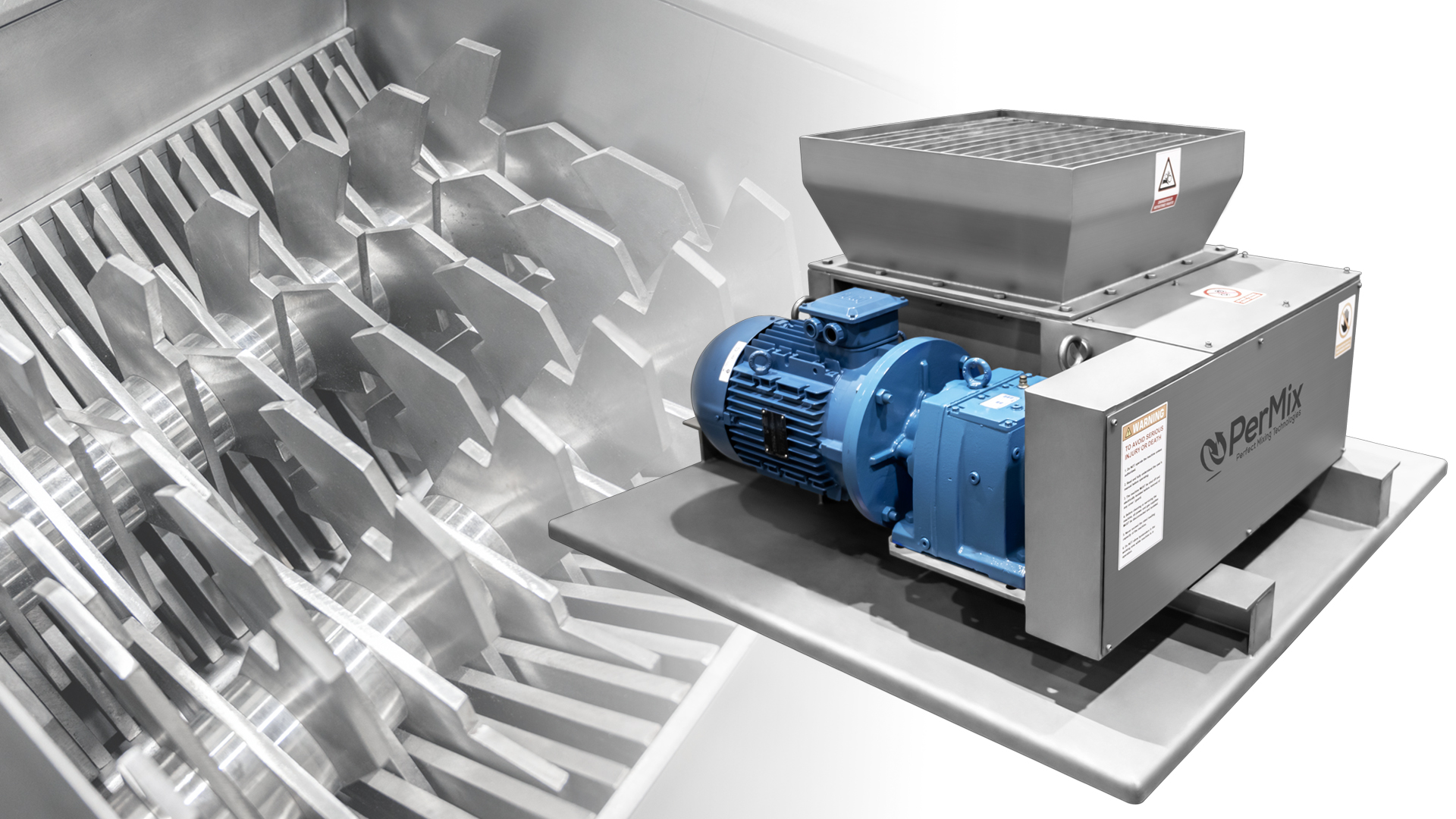

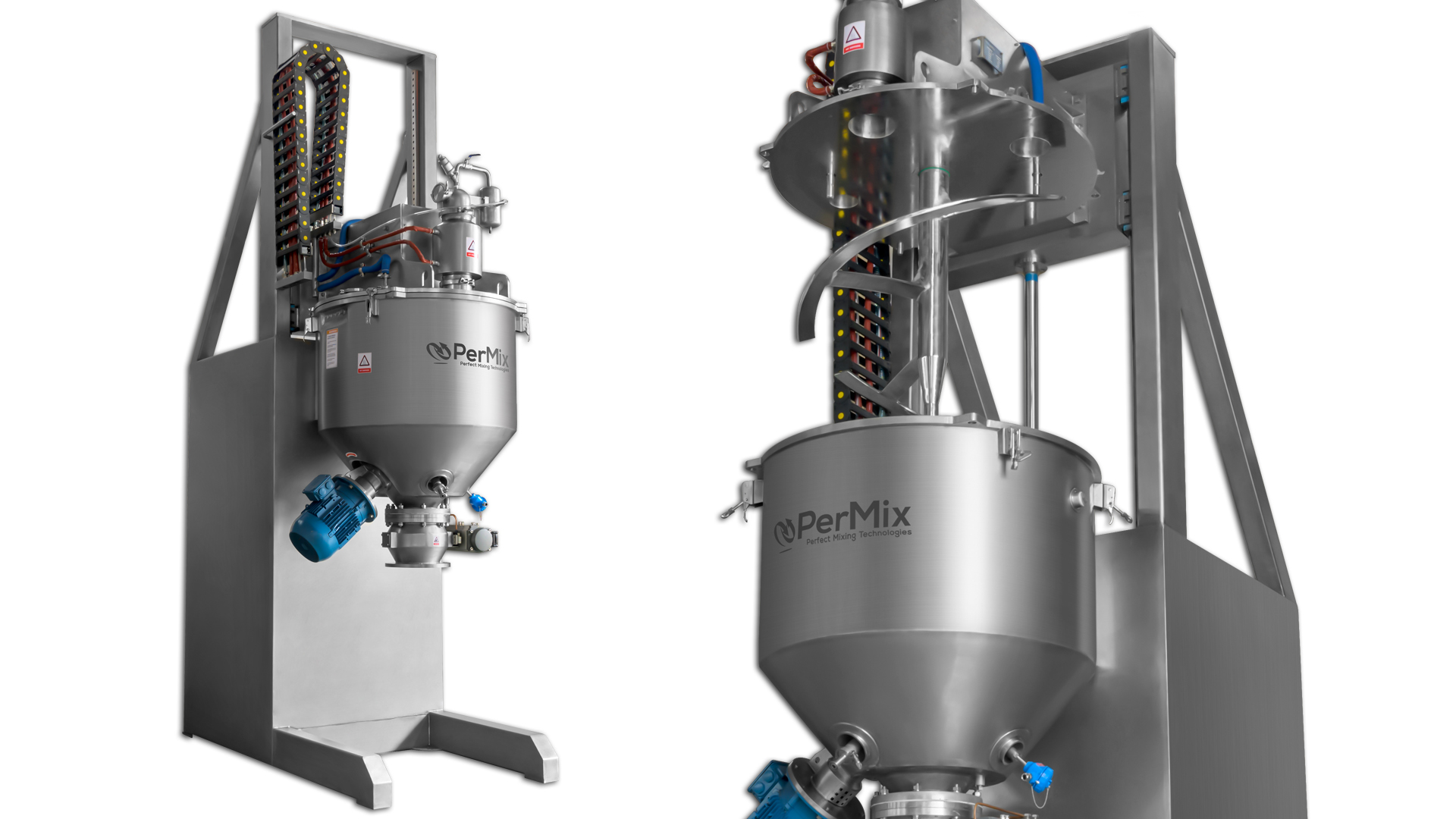

The mixing of graphite into concrete presents a unique issue as the density of ingredients varies vastly. When we talk about mixing and mixing products of various densities, the best choice of mixer by far for production purposes are the fluidized zone mixers. These mixers allow for quick mixing of various density products while having a zero to low shearing effect on the ingredients. The fluidized zone mixers are available in a twin shaft mixer and a single shaft mixer, both of which have very quick batch times that range from 30-60 seconds for the twin shaft model and 3-4 minutes for the single shaft models.

In conclusion, mixing graphite into concrete offers a range of significant benefits. From improved thermal and electrical conductivity to enhanced strength, durability, self-lubrication, and corrosion resistance, the incorporation of graphite can greatly enhance the performance and lifespan of concrete structures. Incorporating graphite into concrete is a promising approach that opens up new possibilities for various construction projects.