Lean Manufacturing? Mixing & Ingredient Feeding That Focus On Minimizing Time

Lean Manufacturing? Turn-Key Mixing & Ingredient Feeding Systems, From Bulk to Micro That Maximize Lean Manufacturing

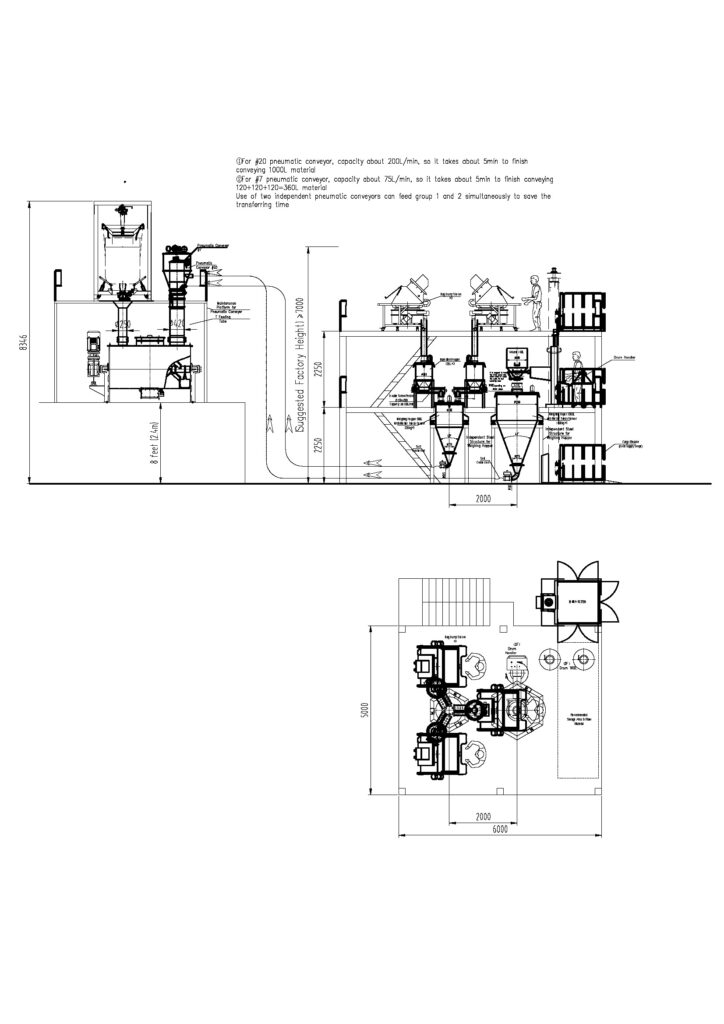

Here is a complete ingredient batching system and mixer system we are doing for Canada. The ingredient feeding system includes 3 gain-in-weight feeders, a drum dump system, bulk bag unloader, and pneumatic conveyor for all three areas into the mixer. Note the elevator for bringing bags up and down to the platform as the gain-in-weight feeders are loaded by bag dump stations with dust collection. The mixer is a PFBS-3000, 3000 liter single shaft fluidized zone mixer.

Batch times mean much more than just mixing times. Loading and unloading are key areas that effect batch times. Maximizing efficiency and. minimizing product loss during batching are crucial areas that increase production as well as increase profit margins. Everything about this system optimized the time and focused on lean manufacturing.

Come see the PerMix difference

#permix#bulkmaterialhandling#ingredients#mixing#mixers#powdermixing#powdermixers#pharmaceuticalmanufacturing#foodmanufacturing#chemicalmanufacturing