Fluidized Zone Mixers Are Key To LEAN Manufacturing for OSF Flavors

PerMix Fluidized Zone Mixers Chosen By OSF Flavors For LEAN Manufacturing Site

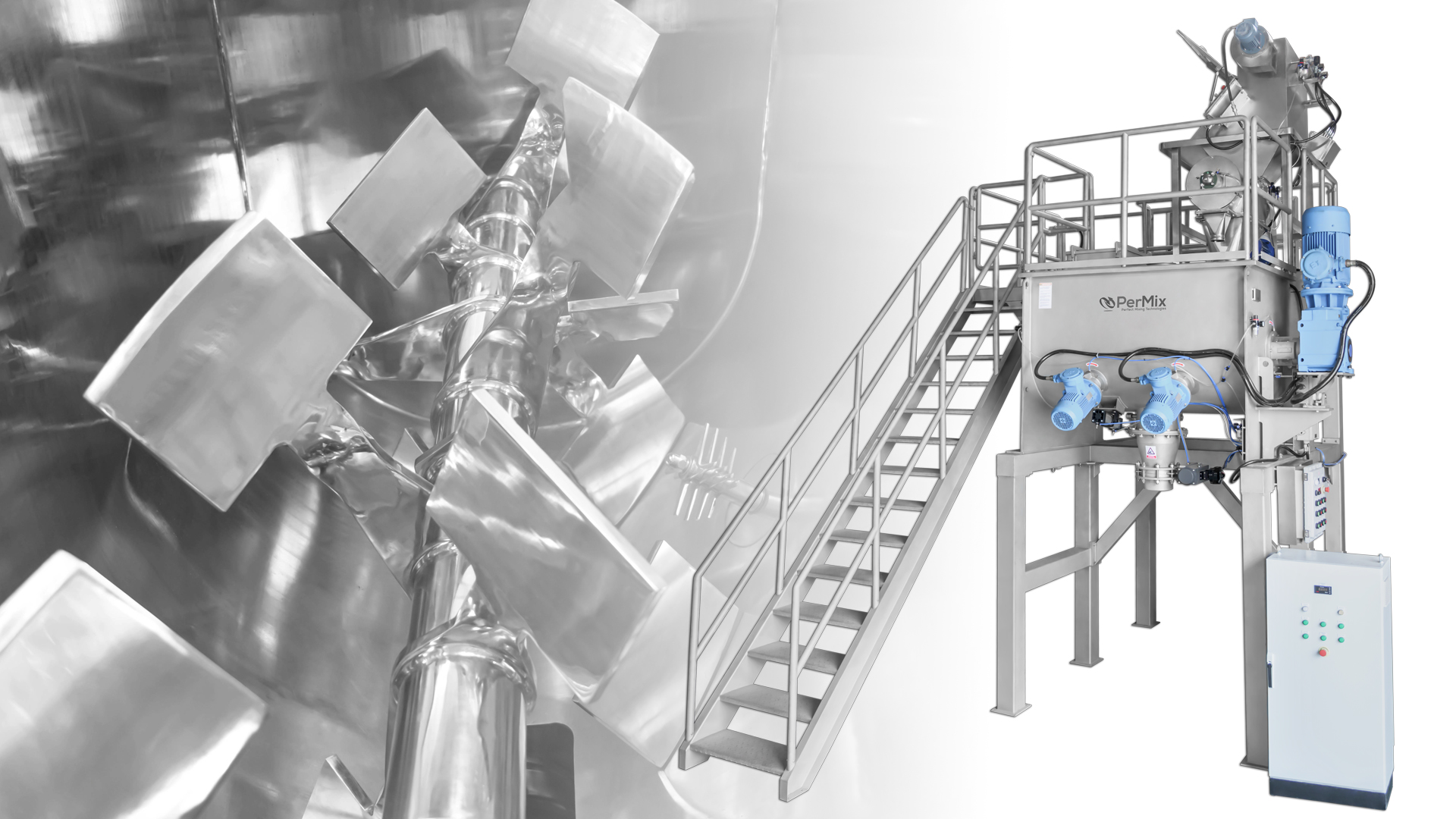

OSF Flavors Expands Production With Two PerMix Fluidized Zone Mixers

When OSF Flavors needed to expand production of their spice and food line, they chose two 500cu.ft PerMix single shaft fluidized zone mixers with sanitary construction. The fluidized paddle mixers include choppers for de-lumping, de-clumping, and de-bumping in the mixer to ensure a quick and homogenous blend of ingredients, with a batch time of 3-4 minutes. This will allow OSF to increase production and decrease labor, as well as operate as part of a LEAN manufacturing facility. To see about the OSF plant and the LEAN manufacturing facility go to http://bit.ly/3hBQF3v

Come see the PerMix difference at www.permixmixers.com

#permix #mixers #mixing #leanmanufacturing #foodmanufacturing #sustainableworld #energy #flavors #OSFFlavors #ecology