Double Planetary Mixers, With Or Without Vacuum?

Double Planetary Mixers, With Or Without Vacuum?

Double planetary mixers are one of the most popular and versatile mixing solutions available on the market today. They can be used for a wide range of applications, from mixing small batches of specialty products to large-scale industrial production runs. But when it comes to double planetary mixers, there is one important question that needs to be answered: should you opt for a mixer with or without vacuum?

In this blog post, we’ll explain the advantages and disadvantages of each type of mixer and guide you through the process of making the right choice for your application.

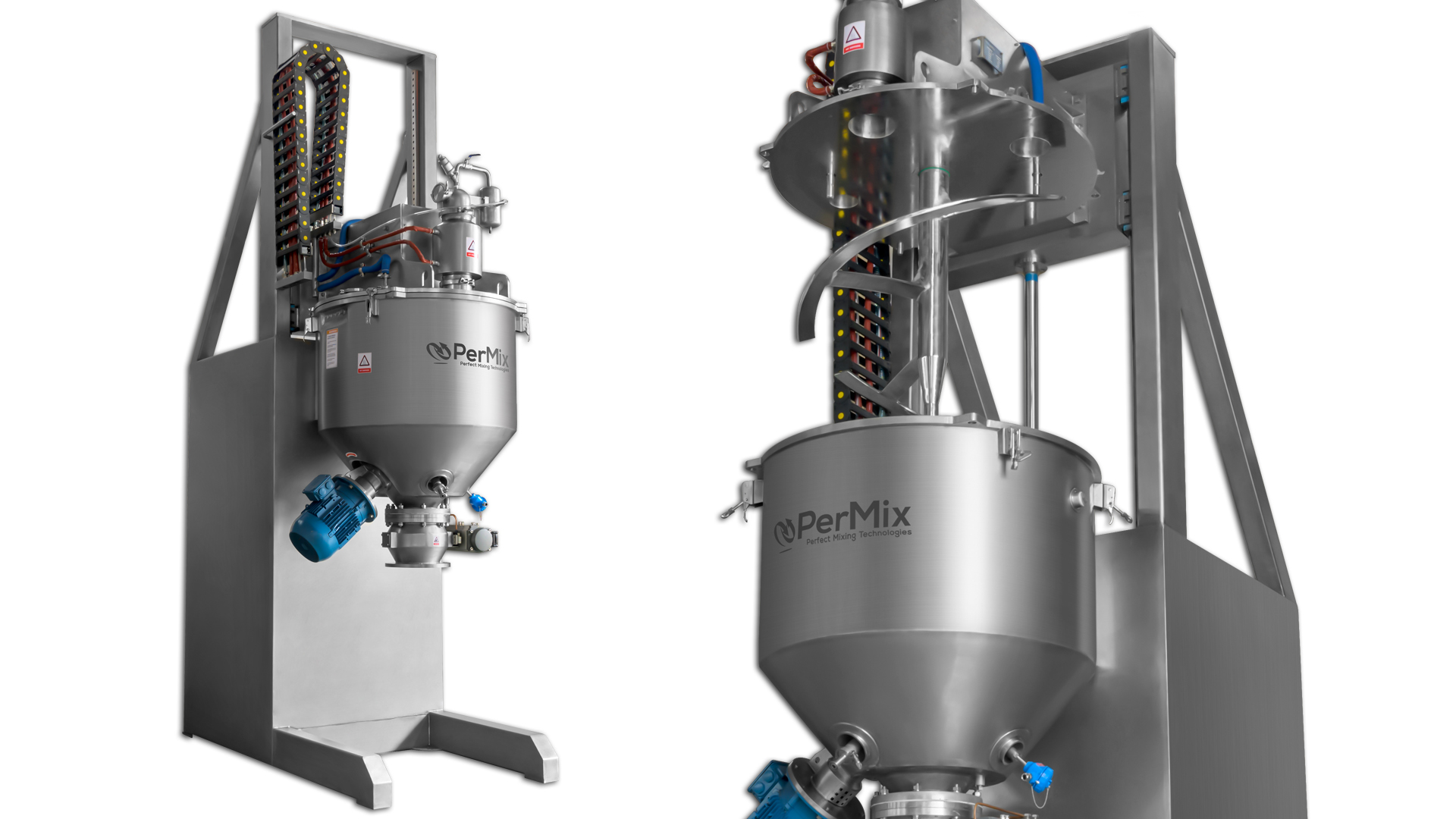

What is a Double Planetary Mixer?

Before we get into the details of whether or not to choose a mixer with or without vacuum, let’s take a closer look at what a double planetary mixer is.

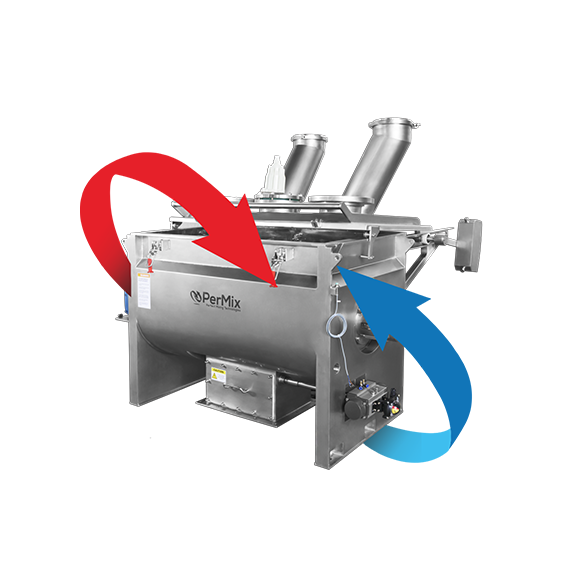

A double planetary mixer is a type of mixer that consists of two main components: a main vessel, which is usually a cylindrical container, and two blades that move around the vessel in a planetary motion. As the blades rotate, they mix the contents of the vessel, allowing for a thorough and even mix.

The main advantage of double planetary mixers is that they can be used for a wide range of applications, from mixing small batches of specialty products to large-scale industrial production runs. They are also capable of producing a homogenous mix in a shorter amount of time than other types of mixers.

Vacuum Mixers

Now that we have a better understanding of what a double planetary mixer is, let’s take a look at the advantages and disadvantages of using a mixer with vacuum.

The main advantage of using a mixer with vacuum is that it can reduce the amount of air that is mixed into the product. This is especially beneficial when it comes to mixing products that are sensitive to oxidation or when the mix needs to be free from air bubbles. Vacuum mixers also help to reduce the temperature of the mix, which can be beneficial for products that are temperature-sensitive.

The main disadvantage of using a mixer with vacuum is that it requires more power than a mixer without vacuum. This is because the vacuum has to be maintained in order to achieve the desired results. Additionally, vacuum mixers are more expensive and require more maintenance than mixers without vacuum.

Non-Vacuum Mixers

Now let’s take a look at the advantages and disadvantages of using a mixer without vacuum.

The main advantage of using a mixer without vacuum is that it is typically less expensive and requires less maintenance than mixers with vacuum. Additionally, non-vacuum mixers are able to produce a homogenous mix in a shorter amount of time than mixers with vacuum.

The main disadvantage of using a mixer without vacuum is that it may not be able to reduce the amount of air that is mixed into the product or reduce the temperature as effectively as a mixer with vacuum. Additionally, non-vacuum mixers may not be as effective when it comes to mixing products that are sensitive to oxidation.

Which Type of Mixer is Right for You?

When it comes to choosing between a mixer with or without vacuum, it really comes down to what your specific application requires. If you are looking for a mixer to mix small batches of specialty products or are looking for a mixer that can reduce the amount of air that is mixed into the product, then a mixer with vacuum is likely the best option for you. However, if you are looking for a mixer that can produce a homogenous mix in a shorter amount of time or are looking for a less expensive option, then a mixer without vacuum may be the right choice.

No matter what type of mixer you choose, it is important to make sure that you select one that is designed to meet your specific application requirements.

Conclusion

Double planetary mixers can be used for a wide range of applications, from mixing small batches of specialty products to large-scale industrial production runs. When it comes to choosing between a mixer with or without vacuum, it really comes down to what your specific application requires. Vacuum mixers are typically better for applications that require reduced air content or temperature control, while non-vacuum mixers are typically more cost-effective and require less maintenance.

Regardless of which type of mixer you choose, it is important to make sure that you select one that is designed to meet your specific application requirements.

Come see the PerMix difference