Single Shaft Fluidized Zone Mixer To Meets Demands Of Sugar Foods Needs

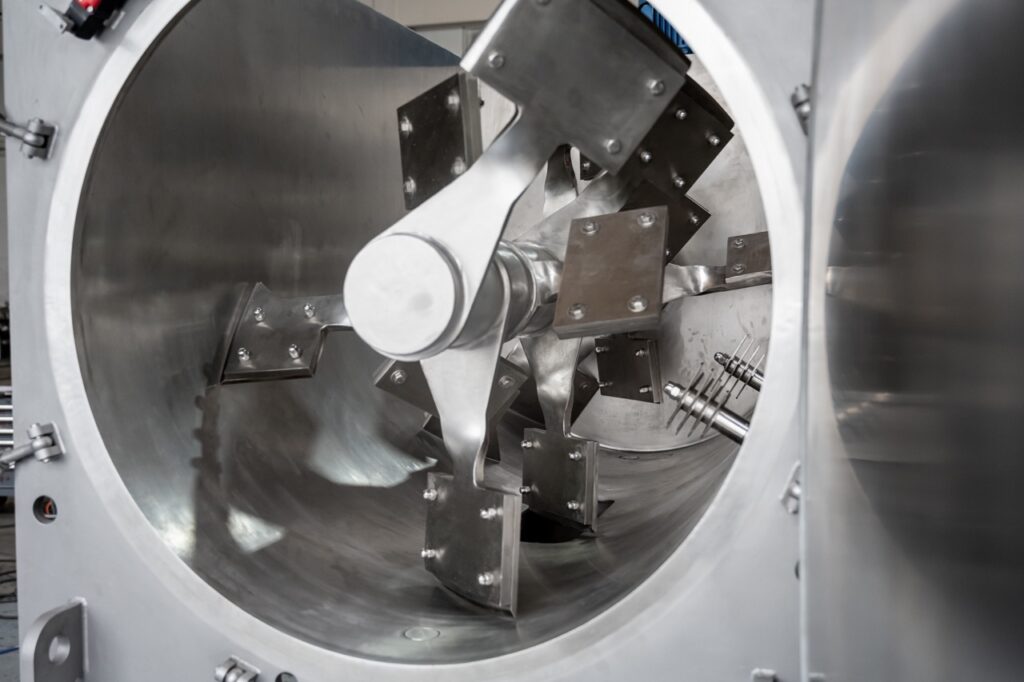

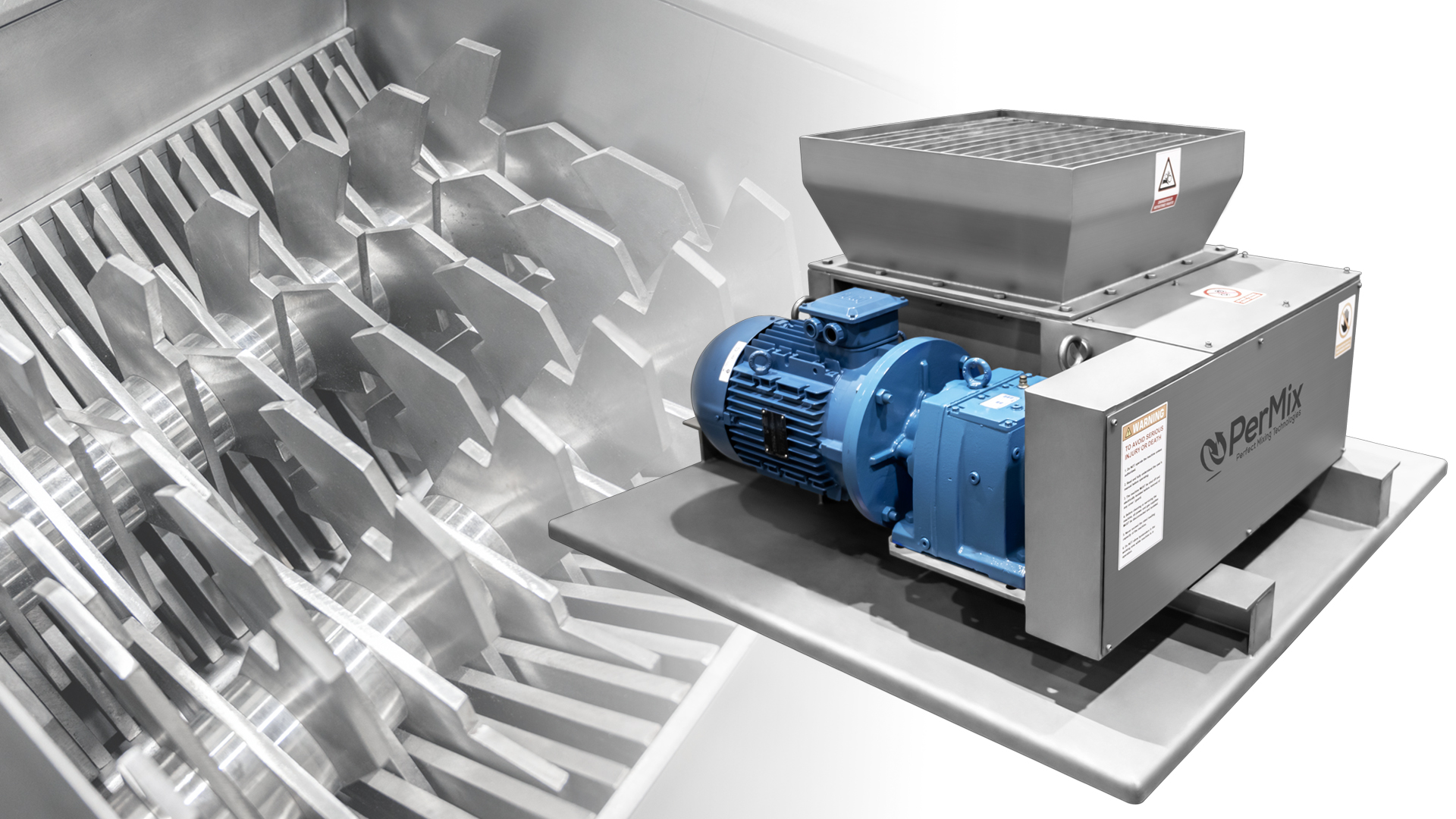

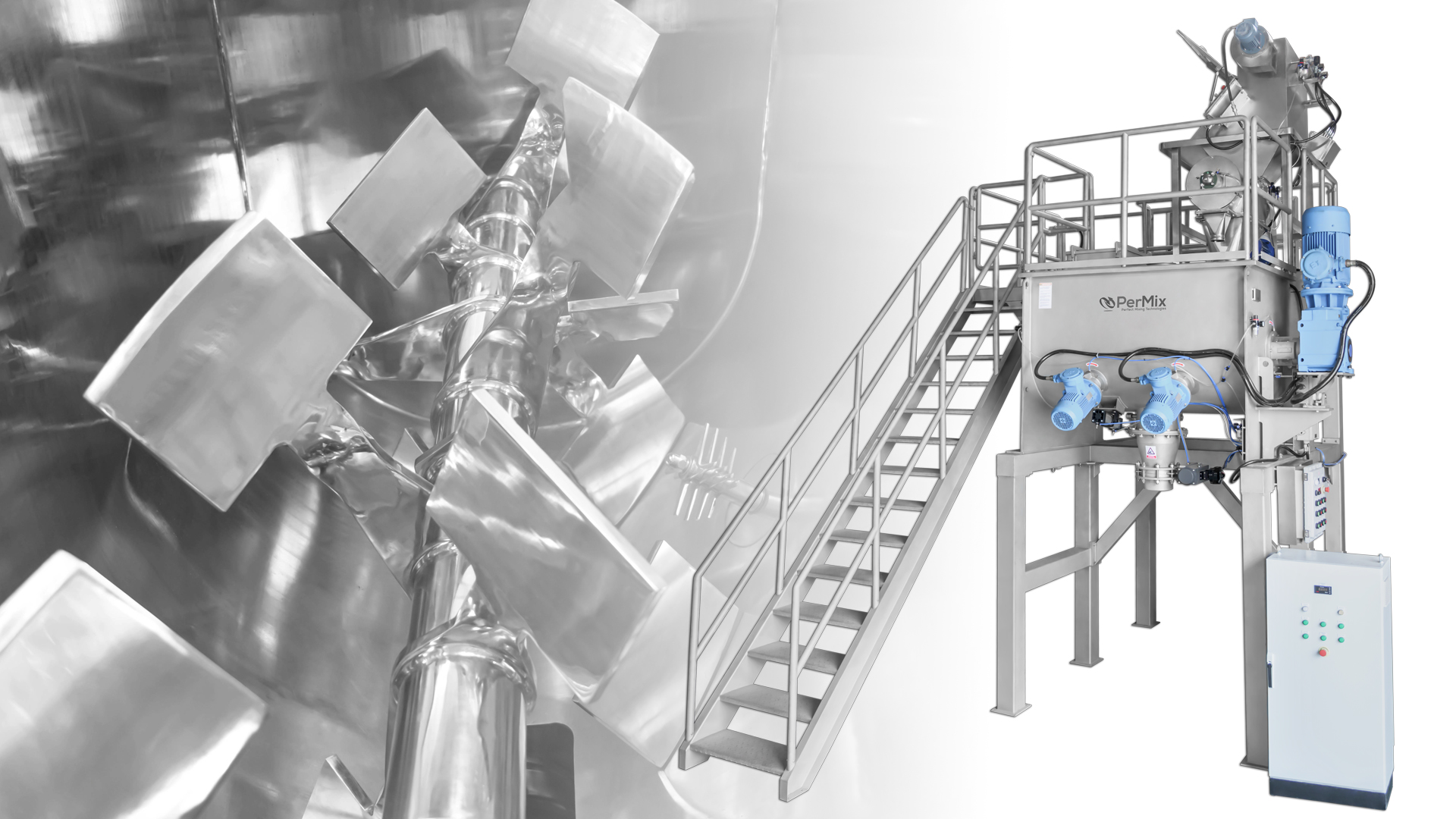

When Sugar Foods in Canada needed a mixer to mix various density of ingredients they turned to the PerMix Single Shaft Fluidized Zone Mixer for their needs. The mixer was custom engineered for their needs with such features as a cantilever designed door that allows for ease of cleaning and eliminated confined space entry. The paddles on the mixer were requested to be bolted type, allowing for ease of replacement as the sugar and other ingredients may cause wear on the paddles. The base was requested to be portable so the mixer can be wheeled out of the R&D area for cleaning and maintenance if needed.

Let PerMix custom engineer & build the mixer to maximize your mixing experience. Come see the PerMix difference at www.permixmixers.com

#permix#sugarfoods#mixers#mixing#foodmanufacturing#sugarindustry