Types Of Dual Shaft Mixers And Their Advantages In Mixing

Introduction

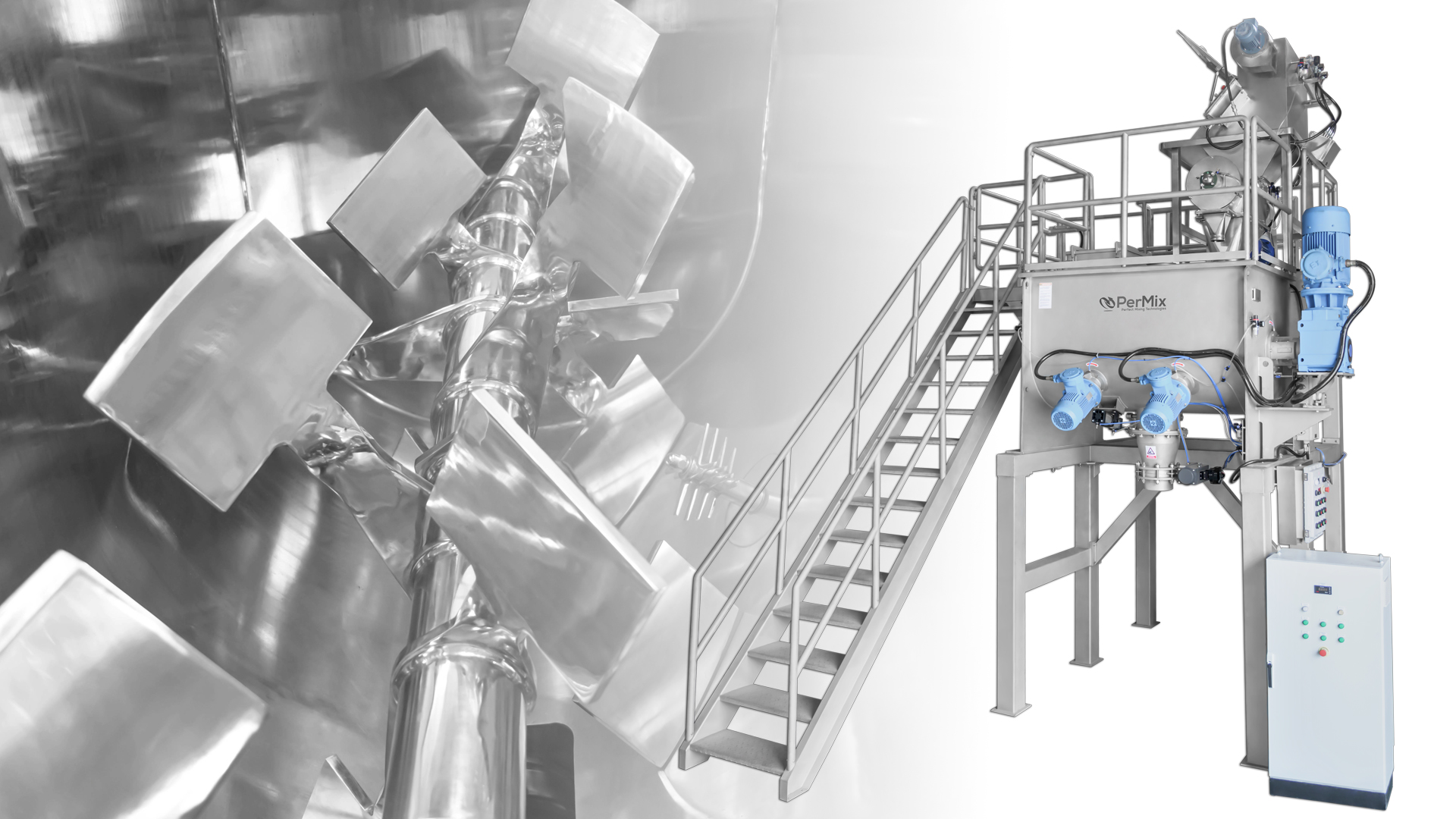

In this PerMix article, we will explore the various types of dual shaft mixers and their advantages in mixing. Dual shaft mixers are versatile and efficient tools used in various industries for blending and homogenizing different substances, from powders & pastes, to liquids. By understanding the different types available and their benefits, you can make an informed decision when choosing a dual shaft mixer for your specific needs.

What are Dual Shaft Mixers?

Dual shaft mixers are specially designed mixing machines that consist of two rotating shafts with various mixing elements attached to them. These mixers are commonly used in industries such as pharmaceuticals, food processing, chemicals, and cosmetics, to name a few. The main purpose of dual shaft mixers is to combine different ingredients or substances thoroughly, ensuring a uniform and consistent mixture.

Benefits of Using Dual Shaft Mixers

Using dual shaft mixers offers several advantages in the mixing process. One key benefit is the enhanced efficiency they provide. The dual shaft design allows for better distribution of the mixing elements, resulting in faster and more thorough blending. Additionally, dual shaft mixers are known for their versatility and ability to handle different viscosities and densities of materials. This makes them suitable for a wide range of applications, from powders, or light liquids to high-viscosity pastes.

Dual Shaft Mixer Types

There are three main types of dual shaft mixers that are commonly used in various industries. These include:

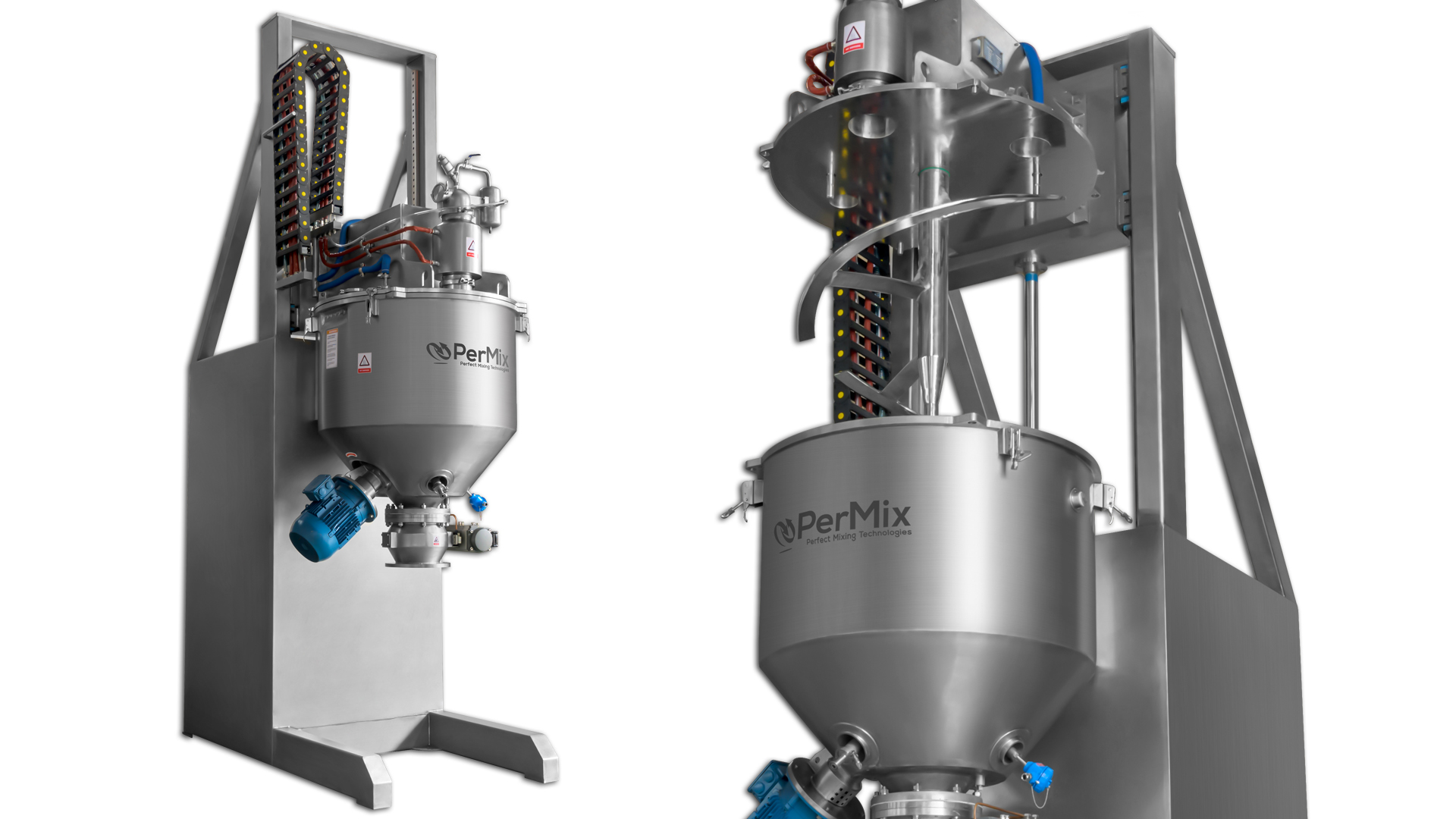

• Vertical Dual Shaft Mixers

Vertical dual shaft mixers are designed with two vertically aligned shafts. This configuration allows for efficient mixing by creating a strong vortex motion in liquids. It is an ideal choice for applications that require intense mixing and dispersion, such as in the production of paints, inks, and adhesives. In powders, the dual shafts rotate and turn, allowing for product to be mixed easily and quickly without shearing.

• Horizontal Dual Shaft Mixers

Horizontal dual shaft mixers have two horizontally positioned shafts that rotate in opposite directions. This design ensures a gentle and thorough mixing action, making it suitable for materials that are sensitive to shear forces. Horizontal dual shaft mixers are commonly used in the bakery, pharmaceutical, and food industry for blending pastes, powders and granules. There are many types of dual shaft mixer available in the horizontal type, from continuous type to batch type, such as our fluidized zone mixers, sigma mixers, and our pin mills

• Planetary Dual Shaft Mixers

Planetary dual shaft mixers feature two mixing shafts that rotate on their own axis while also orbiting around a central axis. This unique motion creates a high level of energy and promotes efficient mixing. Planetary dual shaft mixers are often utilized in the production of high-performance materials, such as advanced ceramics and composites.

• Applications of Dual Shaft Mixers

Dual shaft mixers find applications in various industries due to their versatility and efficiency. Some common applications include:

• Chemical & Paint Industry

• Agricultural Industry

• Pharmaceutical Industry

• Bakery & Food Industry

• Personal Care & Cosmetic Industry

& more…

• Factors to Consider When Choosing a Dual Shaft Mixer

When selecting a dual shaft mixer for your specific needs, it is essential to consider several factors. These include:

• What type of product you are mixing? From powders, pastes, & liquids, there is a type of mixer specific for your needs.

• Continuous or batch type mixing, which type are you doing?

• What is the desired throughput or production needs?

• Do you need any special needs such as heating or cooling, vacuum, pressure, or other?

• Do you need shearing or milling to break up lumps, bumps, or clumps also?

• What type of discharge do you need?

• Conclusion

In conclusion, dual shaft mixers offer a wide range of benefits in the mixing process. Understanding the different types available, their advantages, and considering essential factors will help you make an informed decision when selecting the right dual shaft mixer for your specific application. By following proper maintenance and care practices, you can ensure the longevity and efficient operation of your dual shaft mixer.

That concludes our extensive and detailed blog on types of dual shaft mixers and their advantages in mixing. We hope you found this article informative and helpful in understanding the importance of dual shaft mixers in various industries.