How A Vertical Paddle Mixer Works

How A Vertical Paddle Mixer Works

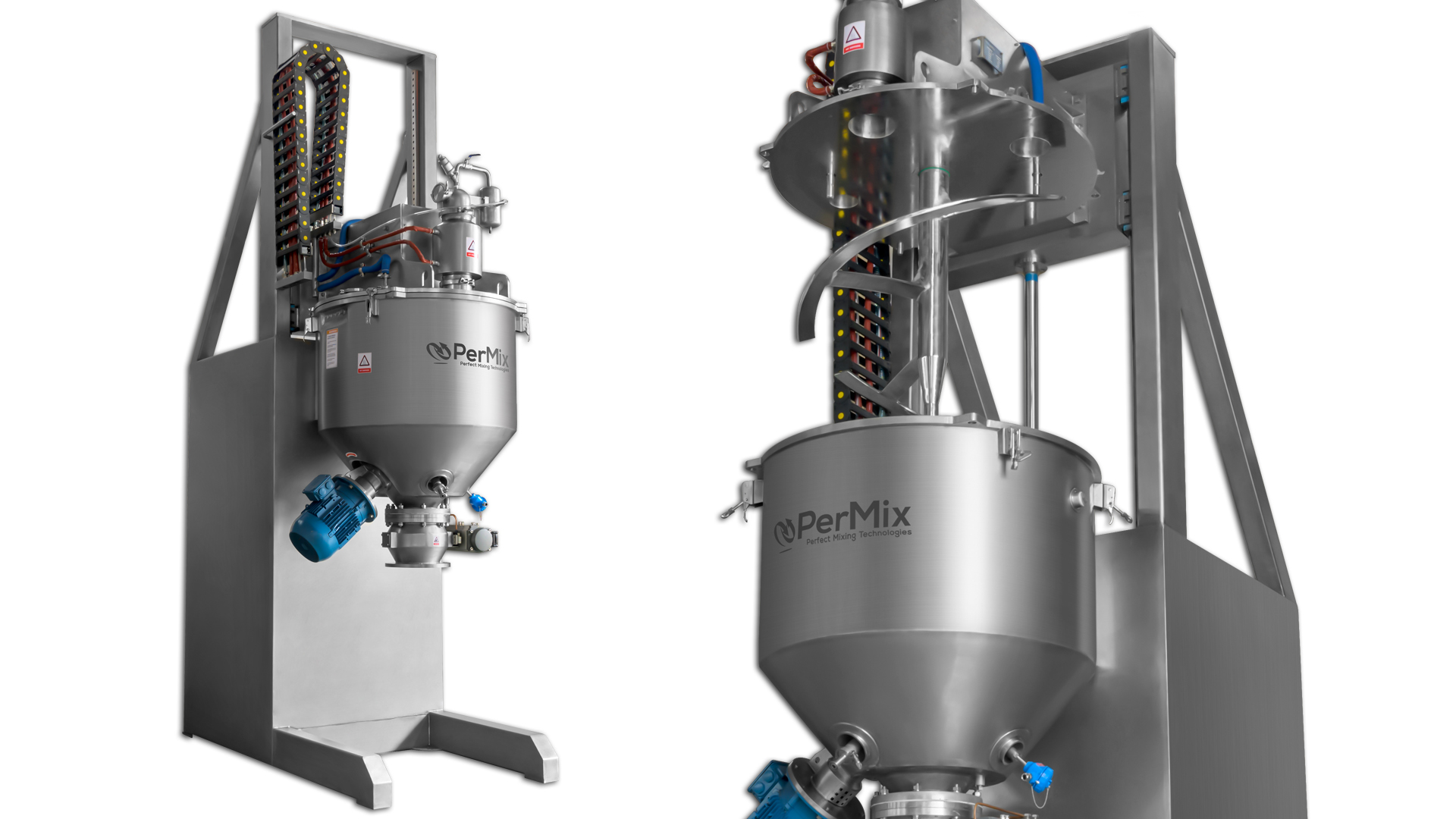

How does a vertical paddle mixer work? A vertical paddle mixer is a type of industrial mixer that is used to mix a variety of materials together. The mixer consists of a large, vertical container with a set of paddles or blades attached to a vertical shaft that runs down the center of the container. When the mixer is turned on, the paddles rotate around the shaft, mixing the materials in the container.

The Components of a Vertical Paddle Mixer

Vertical container: The vertical container is the main body of the mixer. It is typically made of heavy-duty steel and can hold a large volume of materials.

Paddles or blades: The paddles or blades are attached to the vertical shaft and are responsible for mixing the materials in the container. The number and shape of the paddles can vary depending on the application.

Vertical shaft: The vertical shaft runs down the center of the container and is responsible for rotating the paddles.

Chopper: The mixer is a very low shearing/no shearing type mixer, so it is very efficient yet gentle. When the need arises to resize products, choppers can be included in the design which will aid in resizing ingredients. As they have independent motors, then can be used only as needed.

Motor: The motor is responsible for providing the power to rotate the shaft and paddles. The size of the motor can vary depending on the size of the mixer and the materials being mixed.

Jacket: The mixer can be used to heat & cool while mixing by designing the mixer with a jacket. The jacket surrounds the exterior of the mixer, and can be used to heat & cool. One advantage of a vertical mixer is that is has greater surface area in regards to heating and cooling than a horizontal mixer does.

Internal Vacuum: The mixer can also be engineered with internal vacuum, which adds to the efficiency of drying when mixing, should you need to dry a product also. The vacuum can include a condensing column and tank should you need to recover condensate.

How Does a Vertical Paddle Mixer Work?

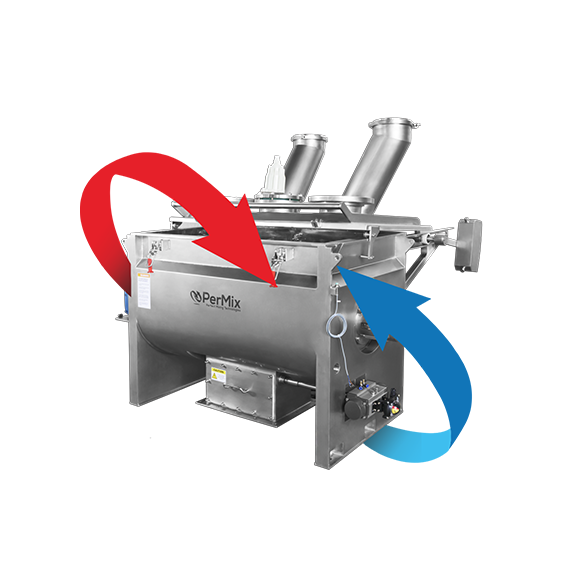

Mixing Process: The mixing process begins when the materials are loaded into the vertical container. Once the container is loaded, the motor is turned on and the paddles begin to rotate. As the paddles rotate, they pick up the materials and mix them together.

Mixing Time: The amount of time required to mix the materials can vary depending on the type and volume of materials being mixed. However, most mixers have a set mixing time that can be adjusted depending on the application.

The Advantages of a Vertical Paddle Mixer

Efficient Mixing: A vertical paddle mixer is an efficient way to mix large volumes of materials together. The mixing process is quick and thorough, ensuring that the materials are evenly mixed.

Low Maintenance: Vertical paddle mixers are designed to be low maintenance. They are made of heavy-duty materials that are designed to withstand the rigors of industrial use.

Versatility: Vertical paddle mixers can be used to mix a variety of materials, including powders, granules, and liquids. They are commonly used in industries such as food, pharmaceuticals, and chemicals.