Granulating and Drying in Double Planetary Mixers

Granulating and Drying in Double Planetary Mixers

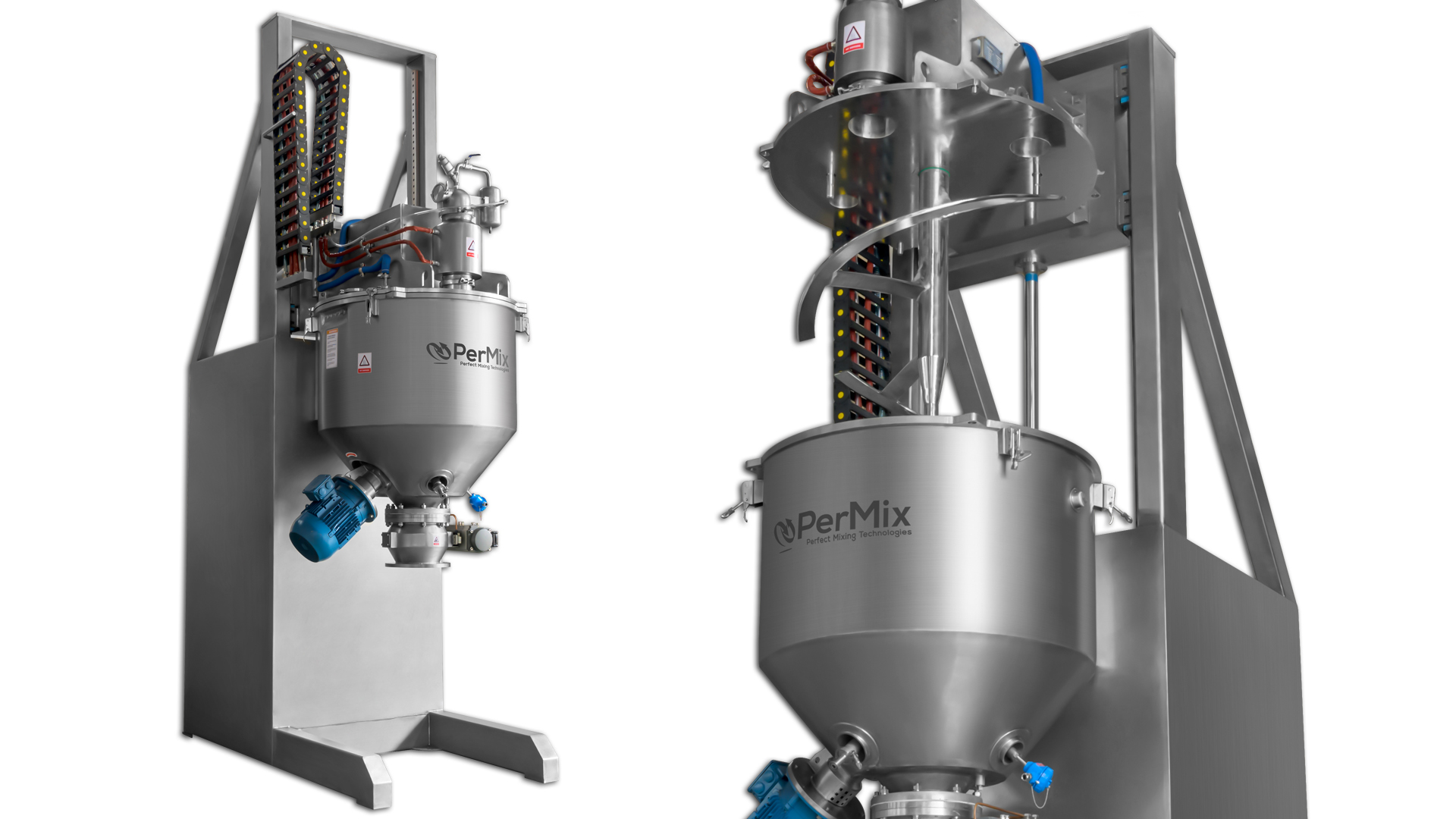

Double planetary mixers are often used in the pharmaceutical, food and chemical industries. They are ideal for mixing, granulating, and drying a range of products. In this blog post, we will discuss the principles of using double planetary mixers for granulating and drying.

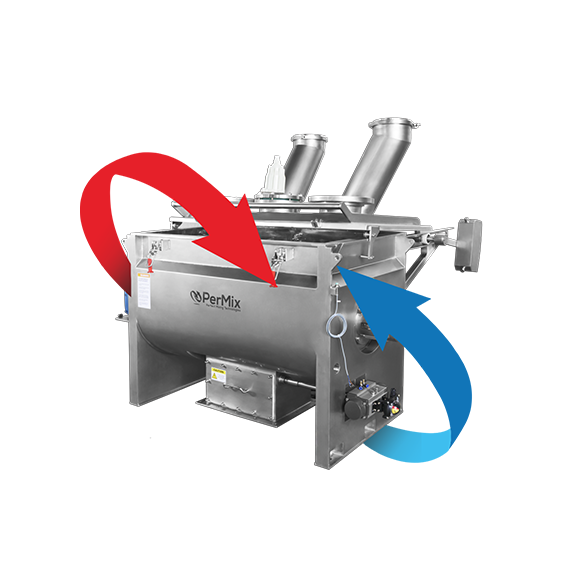

Double planetary mixers are a variation of the traditional planetary mixers. The mixer has two sets of blades, one set rotates around a central shaft, while the other rotates about its own axis as it moves around the central shaft. This creates a more uniform mixing action than with traditional planetary mixers, which can help speed up the granulating and drying process.

Granulating is the process of forming small particles from a bulk material. The small particles are then typically dried and further processed. Granulating in a double planetary mixer is done by adding a binding agent such as a liquid or a powder. The binding agent helps bind the particles together, forming small granules. The granules can then be dried, which helps preserve their shape and size.

Drying involves removing moisture from a material. In double planetary mixers, this is typically done by applying heat. The heat is typically generated by a heating jacket around the mixer, or by using a vacuum system. The heat helps evaporate the moisture, which allows the material to be dried and processed.

Advantages of granulating and drying in a double planetary mixer include:

- Faster and more uniform mixing action, resulting in a shorter drying time.

- The ability to apply a binding agent, resulting in the formation of uniform granules.

- The ability to adjust the heat and vacuum levels, resulting in a more precise drying process.

Disadvantages of granulating and drying in a double planetary mixer include:

- The need for a higher initial investment compared to traditional planetary mixers.

- The need for a more complex control system, which can lead to higher operating costs.

- The need for a higher maintenance effort due to the complexity of the mixer.

In conclusion, double planetary mixers are an excellent choice for granulating and drying a range of products. They provide a faster and more uniform mixing action, as well as the ability to apply a binding agent and adjust the heat and vacuum levels. While they require a higher initial investment and more complex control system than traditional planetary mixers, these disadvantages are offset by the increased efficiency and accuracy of the mixing and drying process.