Using Sigma Mixers & Extruders To Make Silicones

Using Sigma Mixers To Make Silicones

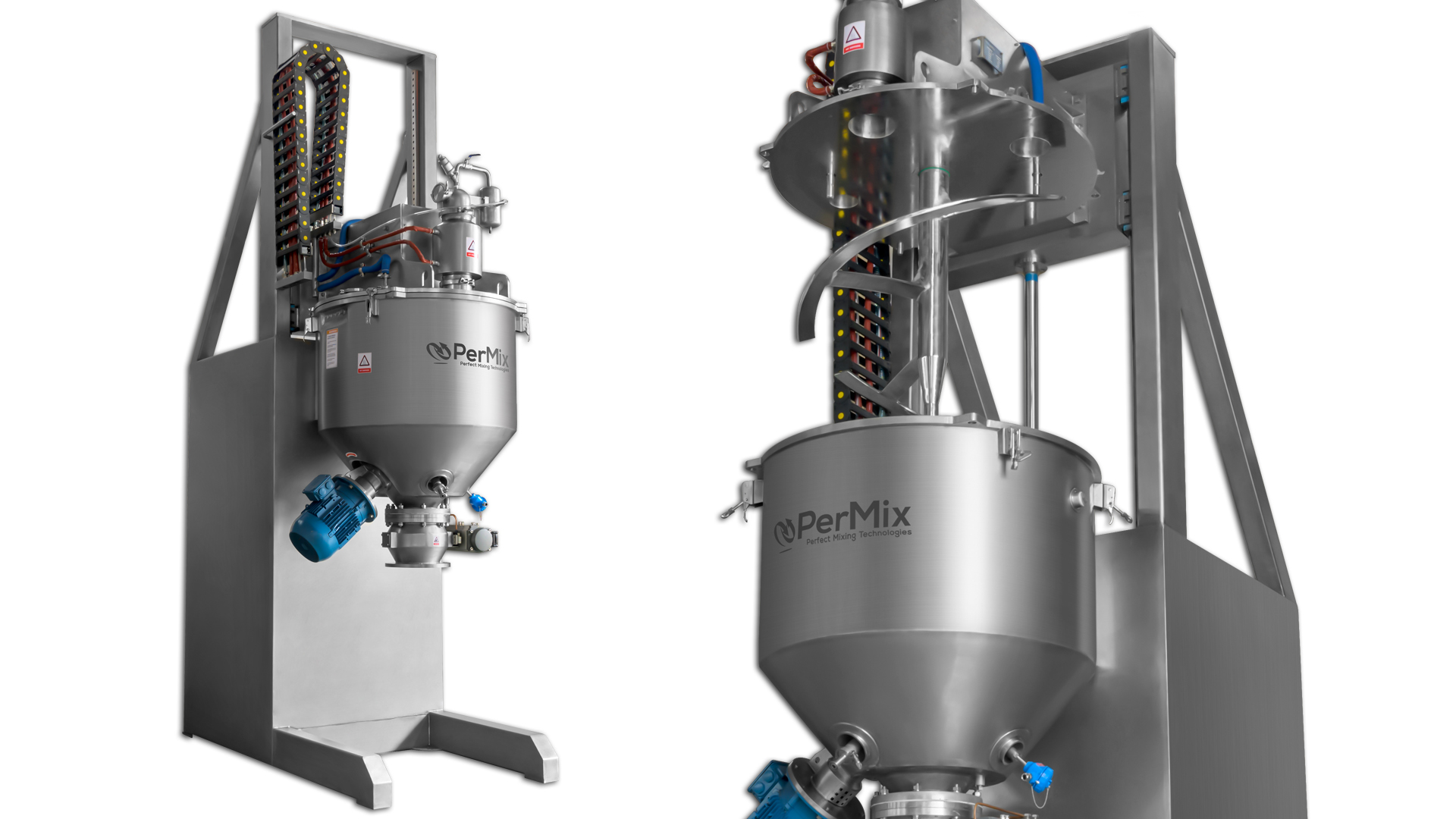

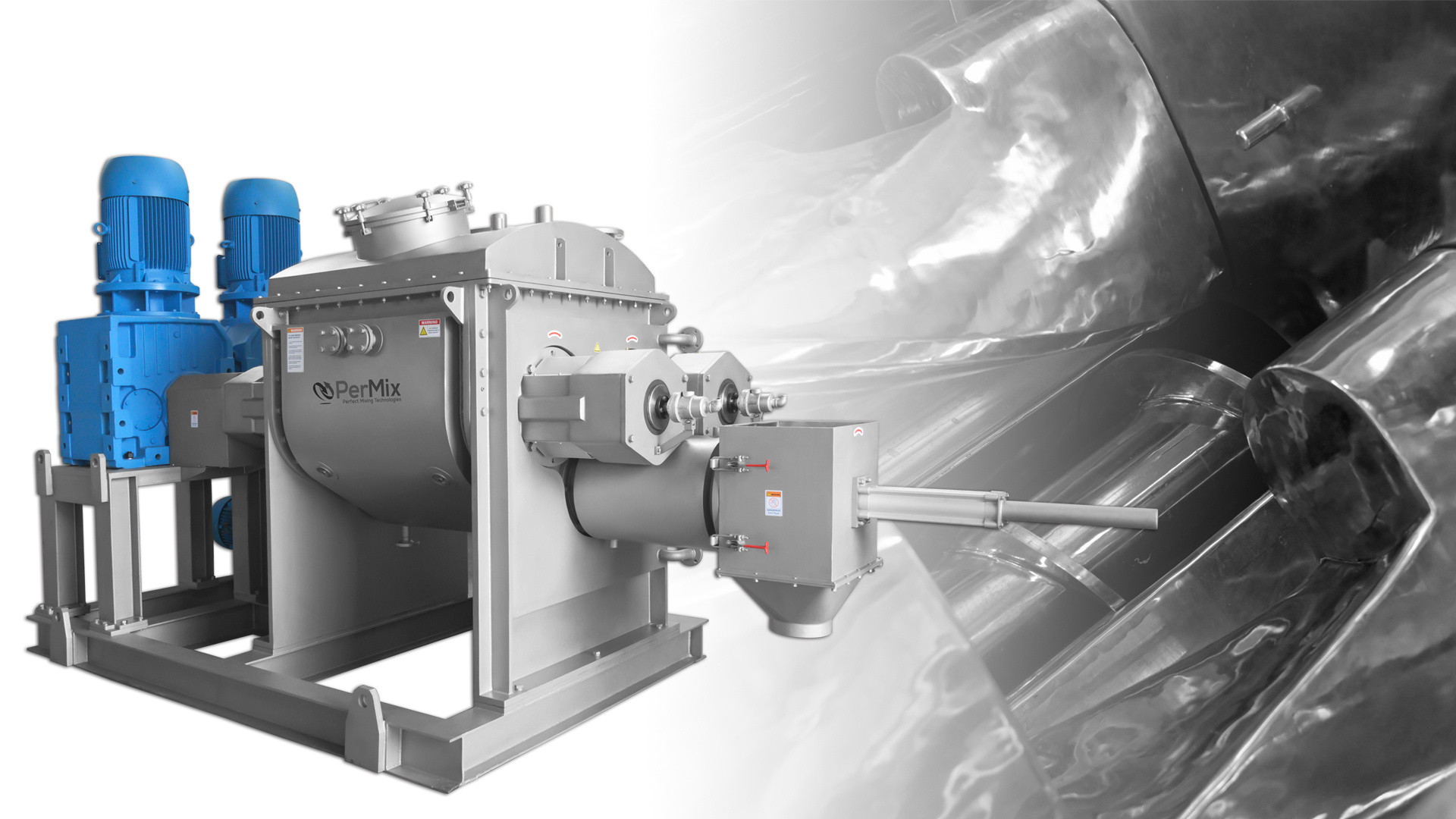

Sigma mixers are versatile and powerful mixing machines used to process a wide range of materials. They are commonly used in the production of silicones, which are a type of synthetic rubber used in many industries such as automotive, construction, and electronics. In this blog, we will discuss the process of making silicones using sigma mixers.

Silicones are a type of synthetic rubber, which is made using a combination of organic and inorganic compounds. They are often used in the production of items such as gaskets, sealants, and adhesives. Silicones are highly durable and resistant to temperature extremes, making them ideal for many applications.

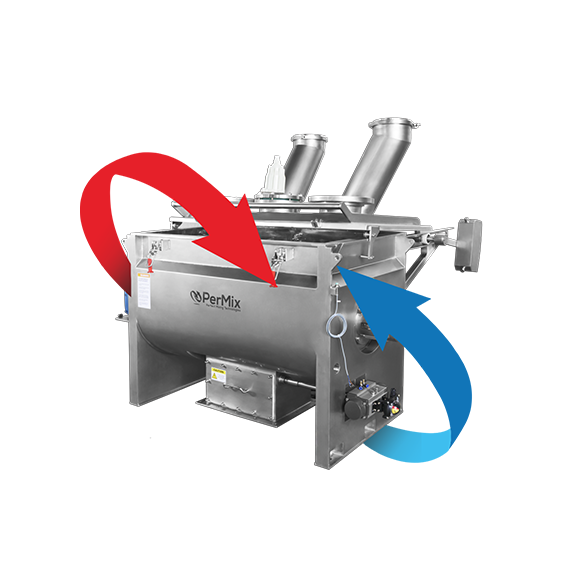

The process of making silicones starts with the mixing of the components. This is done using a sigma mixer, which is a type of mixer that uses a set of rotating blade to mix the materials. The sigma mixer is designed to mix a wide range of materials, including powders, liquids, pastes, and gels. The sigma mixer can also be used to homogenize the mixture, which is an important step in the process of making silicones.

When mixing the components, it is important to ensure that the ingredients are mixed thoroughly. This is because if the ingredients are not mixed properly, the final product may not have the desired properties. Additionally, it is important to ensure that the mixing process is done in the appropriate temperature range. Too much heat can cause the ingredients to react in an undesired way, leading to a poor-quality product.

Once the ingredients have been mixed, the mixture is then heated and cooled. During the heating process, the mixture is brought to a temperature that is high enough to allow for the polymerization process to take place. This process is necessary for creating silicones. After the polymerization process is complete, the mixture is then cooled to room temperature.

Once the mixture has cooled to room temperature, it can then be poured or extruded into molds and allowed to set. After the silicone has set, it can then be removed from the molds and used in its intended application.

Overall, sigma mixers are an essential tool for the production of silicones. They are designed to mix a wide range of materials, including powders, liquids, pastes, and gels together. Additionally, they are capable of homogenizing the mixture and controlling the temperature during the heating and cooling processes. By using sigma mixers, manufacturers can create high-quality silicones for a variety of applications.