Polymer Mixers: Types, Styles, & How They Work

Polymer Mixers Are Available In Many Styles & Sizes

Polymer mixers are an integral part of the plastics and rubber industry. They are used to mix polymers, which are materials made from long chains of molecules. The ability to mix polymers accurately is essential to achieving desired physical properties, such as strength, flexibility, and durability.

Polymer mixers can be used for a variety of applications, including the manufacture of plastics, rubber, coatings, adhesives, sealants, and other materials. They are also used in the production of composite materials, such as fiberglass and carbon fiber.

Types of Polymer Mixers

There are several types of polymer mixers available on the market. The most common types include:

- Single-Screw Mixers & Extruders

- Twin-Screw Mixers & Extruders

- Sigma Mixers & Extruders

- High-speed mixers

- High-viscosity mixers

- Dispersion mixers

Single-Screw Mixers & Extruders

Single-screw mixers are the most common type of mixer used in the plastics and rubber industry. They consist of a single rotating screw, which is used to mix the polymer ingredients. Single-screw mixers are typically used for low- to medium-viscosity materials.

Twin-Screw Mixers & Extruders

Twin-screw mixers are similar to single-screw mixers, but they use two rotating screws instead of one. The two screws work in tandem, enabling them to mix polymers with higher viscosity. Twin-screw mixers are often used for high-viscosity materials.

Sigma mixers & extruders are double arm mixers, used in mixing heavy polymers with high viscosity. The flip & fold technology provides a kneading effect, which mixes polymers with high efficiency & accuracy while also giving the user the ability to extrude using one mixer.

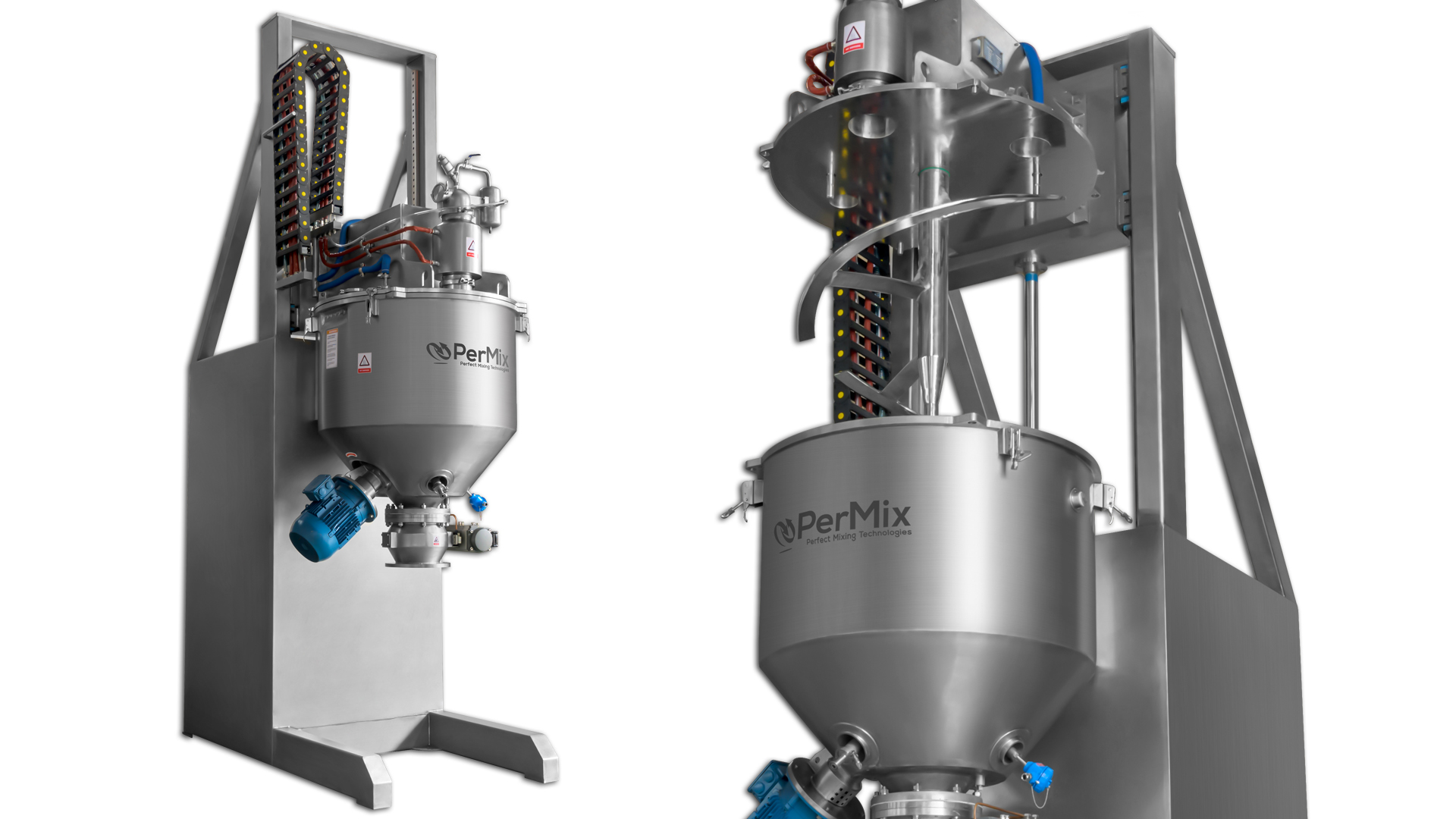

High-Speed Mixers

High-speed mixers are designed to mix polymers at high speeds. They are typically used for high-viscosity materials, as they can achieve a homogeneous mixture more quickly than other types of mixers.

High-Viscosity Mixers

High-viscosity mixers are specifically designed to mix high-viscosity polymers. They use a combination of high shear and high-speed mixing to achieve a homogeneous mixture.

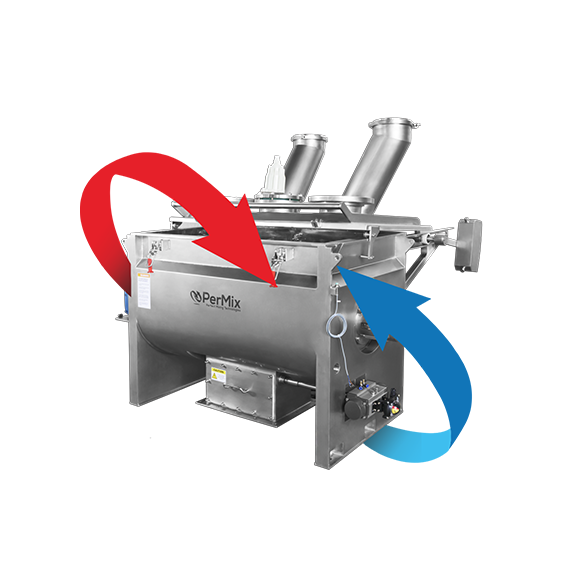

Dispersion mixers use a combination of shearing and blending to mix polymers. They are typically used for low-viscosity materials, as they can achieve a homogeneous mixture without the need for high-speed mixing.

Conclusion

Polymer mixers are an essential tool for the plastics and rubber industry. They are used to achieve the desired physical properties of the final product, such as strength, flexibility, and durability. There are several types of polymer mixers available on the market, including single-screw mixers, twin-screw mixers, high-speed mixers, high-viscosity mixers, and dispersion mixers.