PerMix Sigma Mixers Made Of Titanium Is How Manufacturers Mix Abrasives

How Do Manufacturers Mix Abrasive Powders? They Turn To Titanium Mixers & PerMix

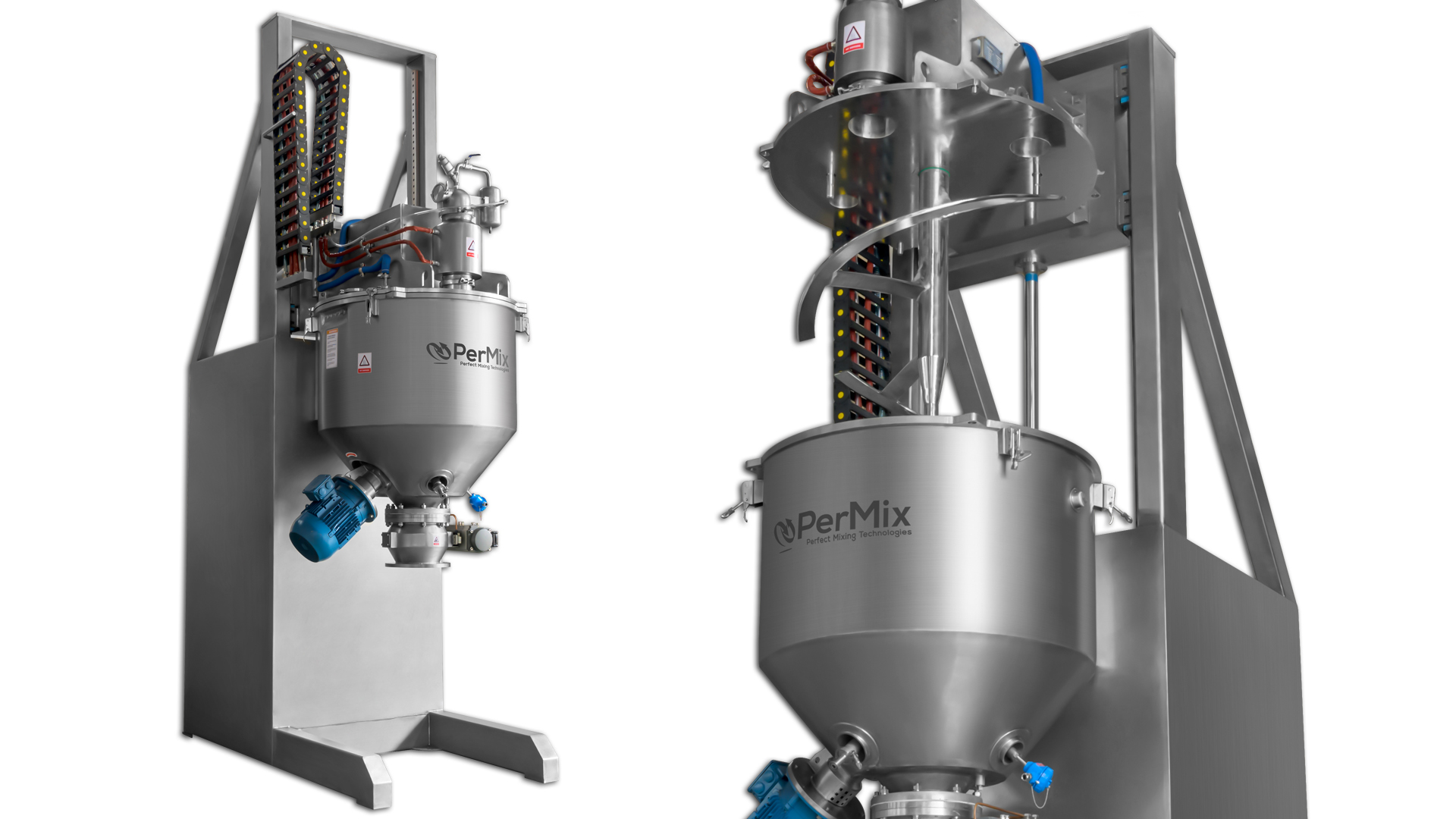

Since 1954 PerMix has been leading the industry with our mixing solutions, setting the standards others follow. Our ability to engineer & manufacture mixers with various metals is a testimonial to our flexibility, including titanium.

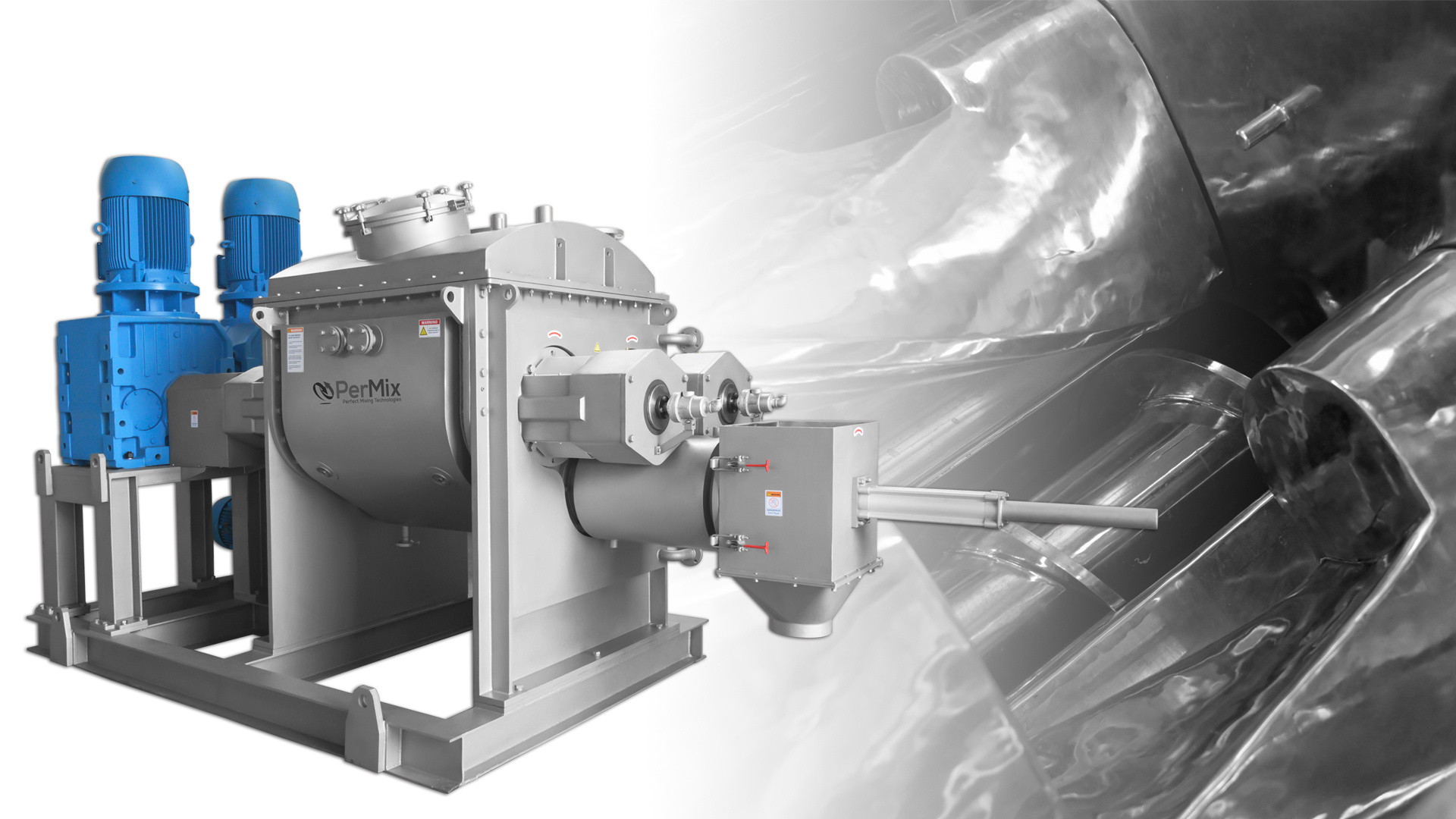

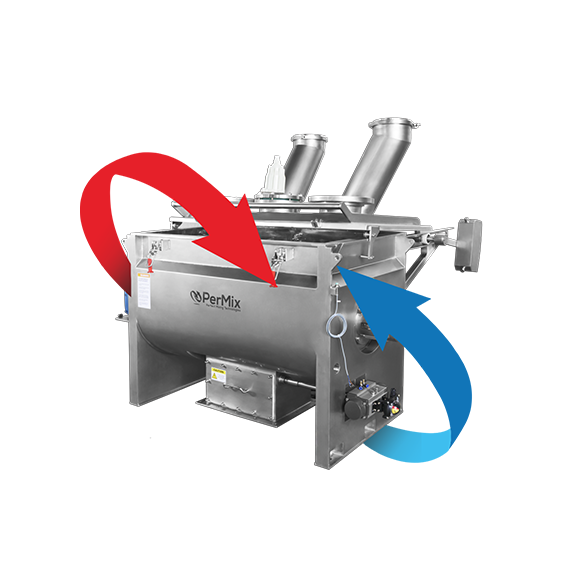

Recently PerMix was contacted by a customer that had a need to mix very abrasive powders with liquids and then after mixing, extrude it. PerMix custom engineered a Sigma Mixer Extruder with titanium contact parts, heating & cooling jacket, internal vacuum, & our “Quick Clean” option which allows the mixer to be totally disassembled in minutes with no tools needed, allowing for easy & quick cleaning.

Our ability to combine innovation, performance, & quality keeps our customers smiling. Come see the PerMix difference

#permix #mixers #mixing #abrasives #powdermixing #powdermixers #vacuumtechnology #sigmamixers #innovation