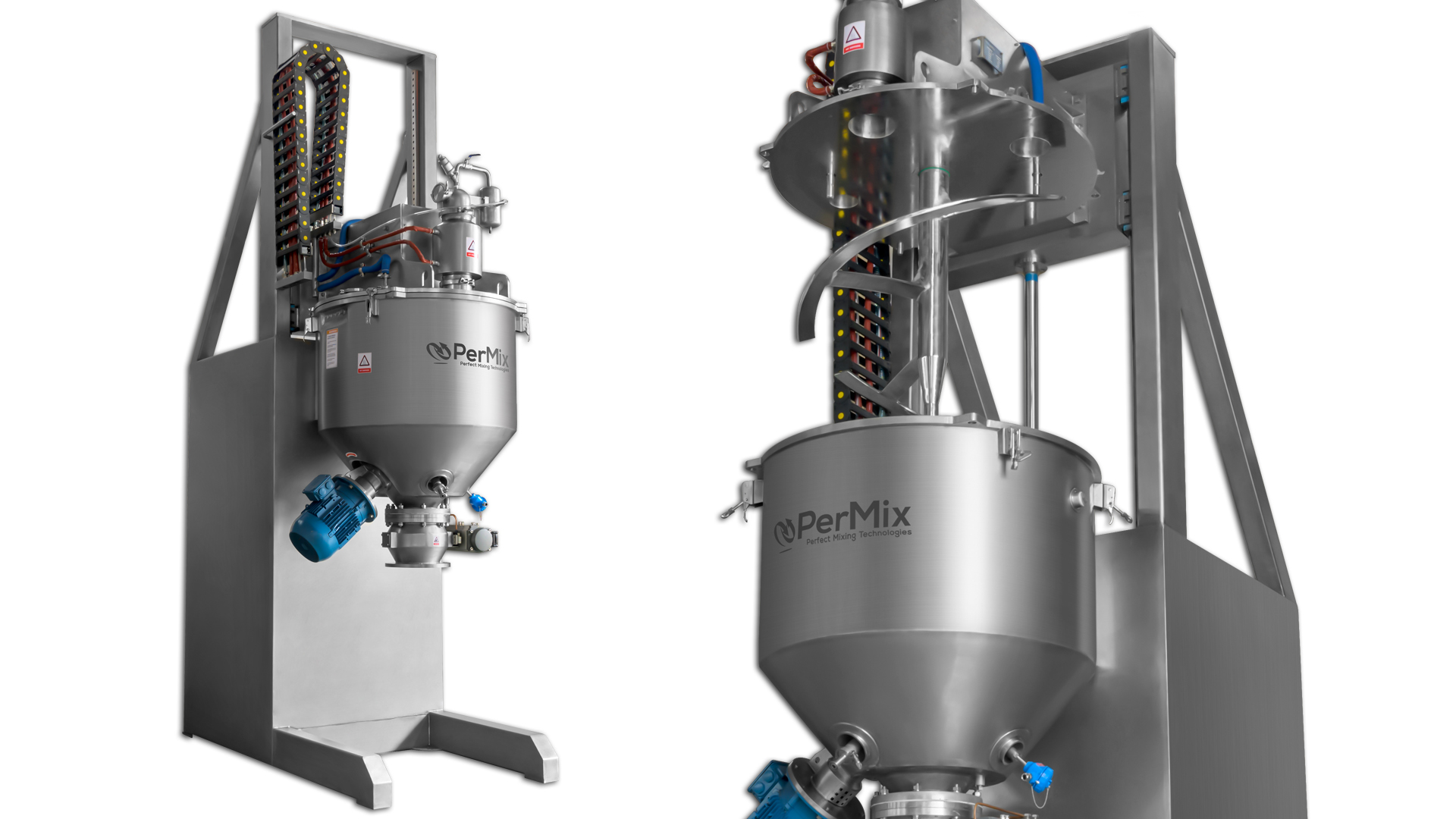

Conical Mixers & Dryers Are Simply The Best

Conical mixers are a batch mixer used widely in mixing applications that require gentle mixing with minimal product distortion, minimal heat generation, and very accurate mixing homogeneity. Since it was first developed more than 60 years ago, it has been recognized as a good solution for products that are delicate, heat sensitive or tending to segregate.

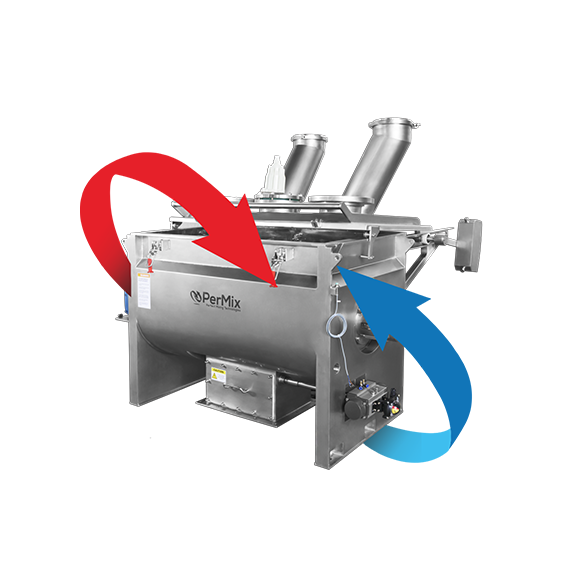

Due to the reason that PerMix Conical Screw Mixer uses gravity to generate the significant downward mass flow, it saves energy compared with a horizontal mixer

These Conical Screw Mixers are also featured with no contamination to the product during the mixing, due to the fact that the shaft sealing & bearing is above the working area, thus no contact with the product.

Inside the PerMix Conical Screw Mixers, there is a cantilevered rotating screw ( or two, three screws according to the specified application) rotating by its own axle which is in parallel to/near the cone vessel.

During the operation, the mixing screw lifts the product around it from the top and then the powder falls down due to the gravity causing a convective mixing. At the same time, the screw is supported by an orbital arm and is rotating around the center of the cone-like a planetary, so that the powders in every corner of the cone can be mixed by the screw, and a 3-dimensional mixing performance occurs within the whole cone.

PerMix also provides you with various options such as:-

* Feeding & Discharge

* Screw Type

* Drive System

* Construction Material and Finish

* Spray Nozzle

* Heating/ Cooling Jacket

* Vacuum drying & de-aerating

The PerMix Conical Mixer is suitable for various applications such as:-

* Gentle mixing of free-flowing powders, pastes and slurry

* Coating of solid mass, powdery product

* Moistening of fine powders

Drying of wet powders, pastes and slurry with vacuum and liquid recovery

Come see the PerMix difference at www.permixmixers.com or www.permixmixers.mx

#conicalmixer#permix#technology#engineering#industrialmixing#foodindustry#manufacturing#foodmanufacturing#pharmaceuticalmanufacturing#chemicalmanufacturing#mixers#energy