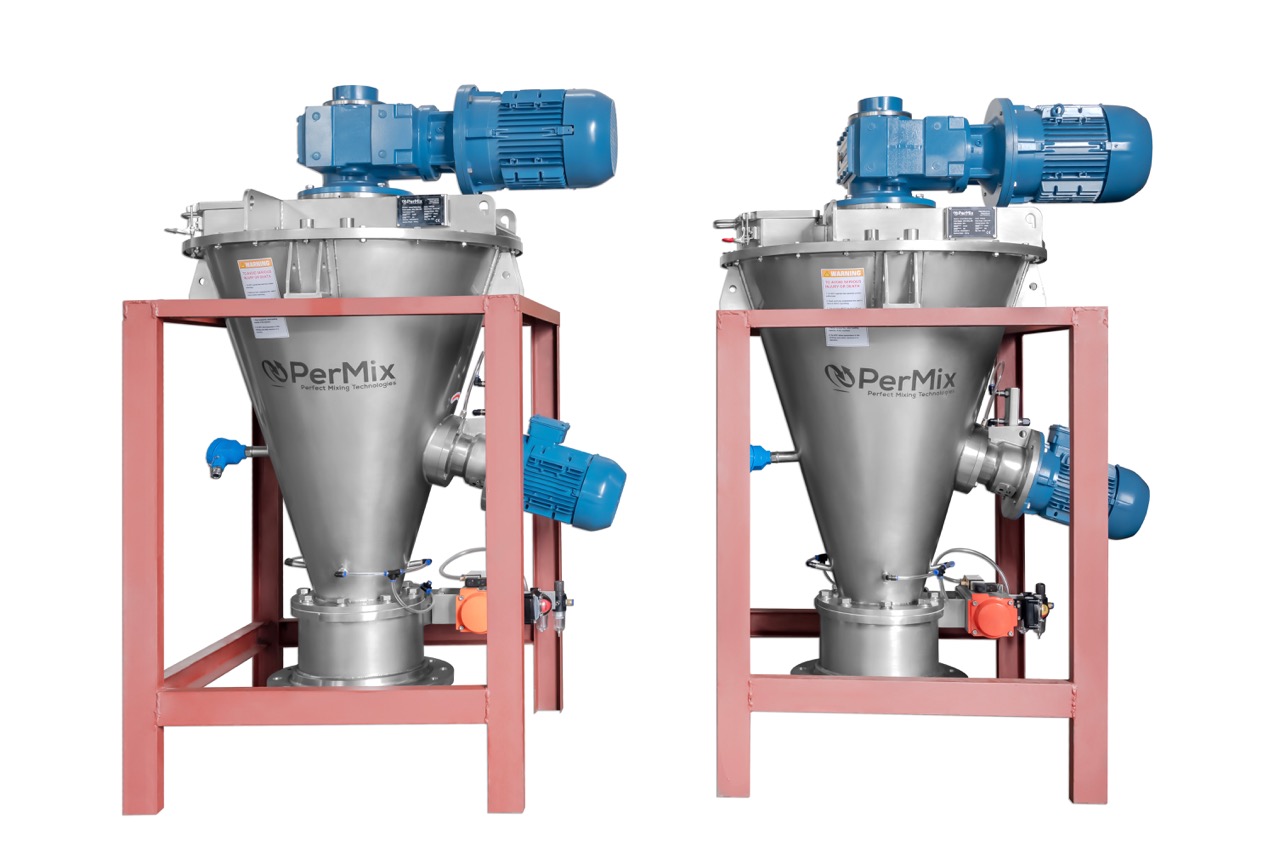

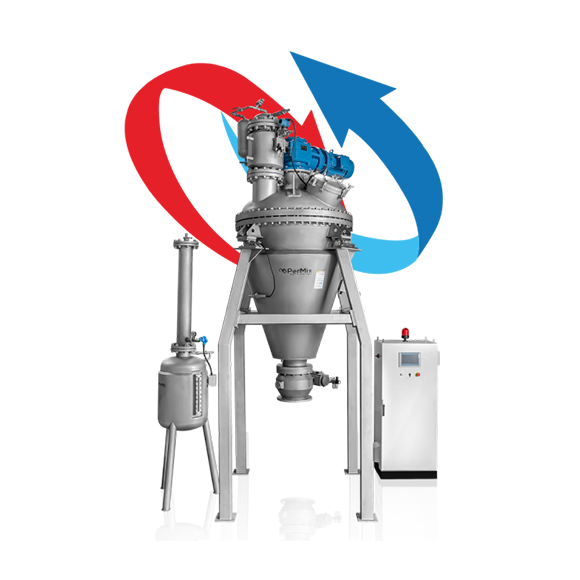

PerMix Vacuum Ribbon Mixers Dryers

PerMix Vacuum Ribbon Mixers & Dryers are sophisticated industrial machines designed for the simultaneous mixing and drying of powders, granules, and bulk materials.

Available in both horizontal and vertical orientations, these mixers and dryers are engineered to operate under vacuum conditions, enhancing the efficiency of the mixing and drying processes while minimizing contamination.