Impact Pulverizers: What They Are & How They Work

? Unlocking Efficiency & Precision in Industrial Operations with Impact Pulverizers! ?

Are you ready to revolutionize your industrial processes? Look no further than the Impact Pulverizer – the powerhouse behind precision grinding and pulverizing in a myriad of industries!

? What is an Impact Pulverizer?

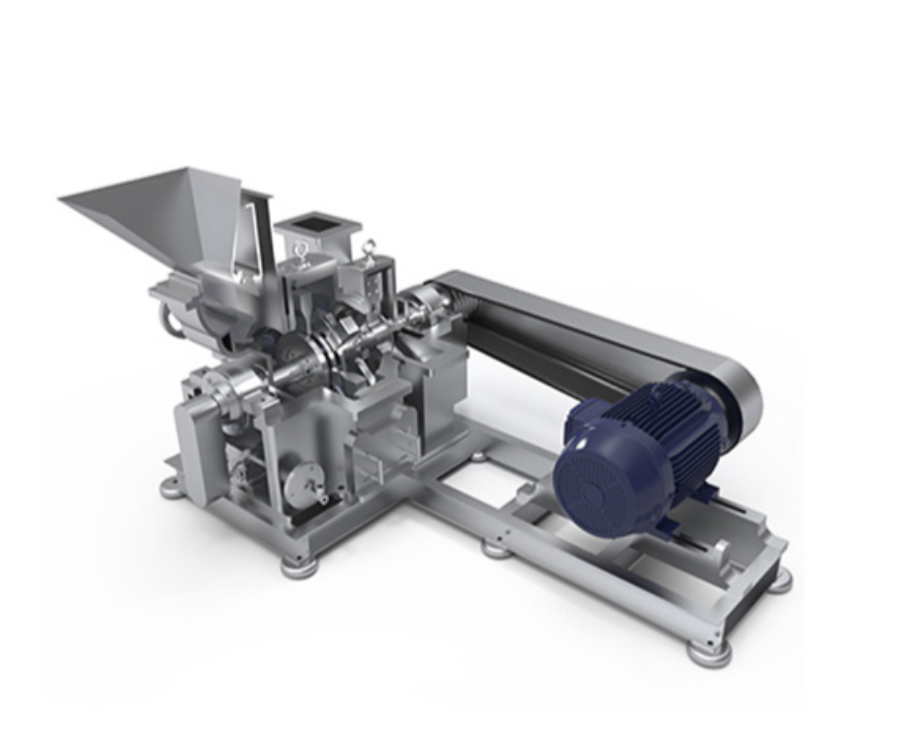

An Impact Pulverizer is a cutting-edge machine designed to crush, grind, and pulverize various materials into fine powders with incredible efficiency. Its robust construction and innovative engineering make it an indispensable tool across diverse industrial sectors.

? How does it work?

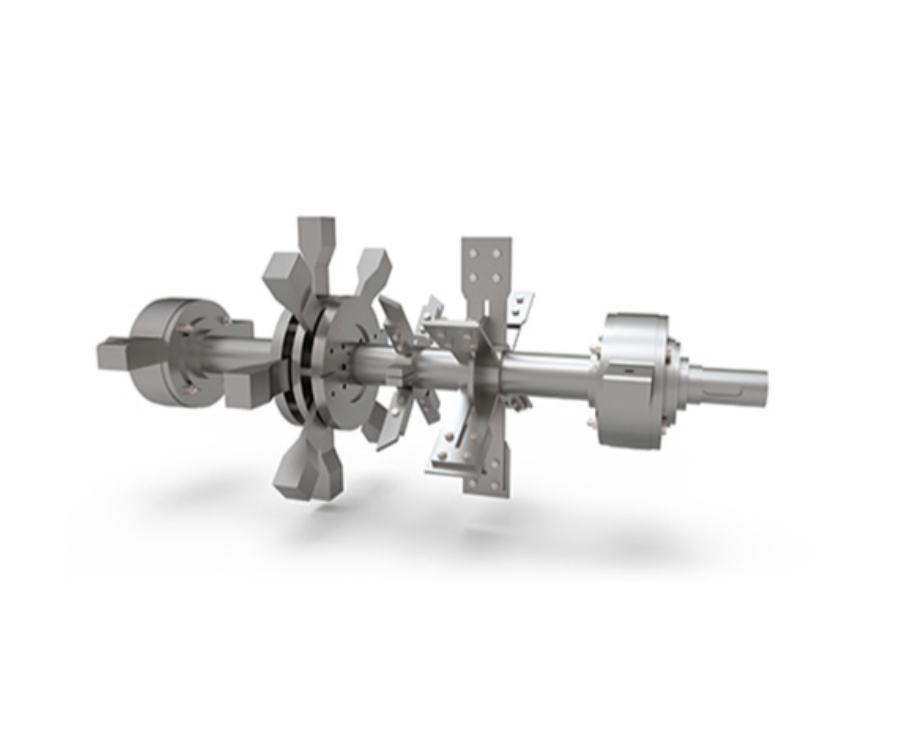

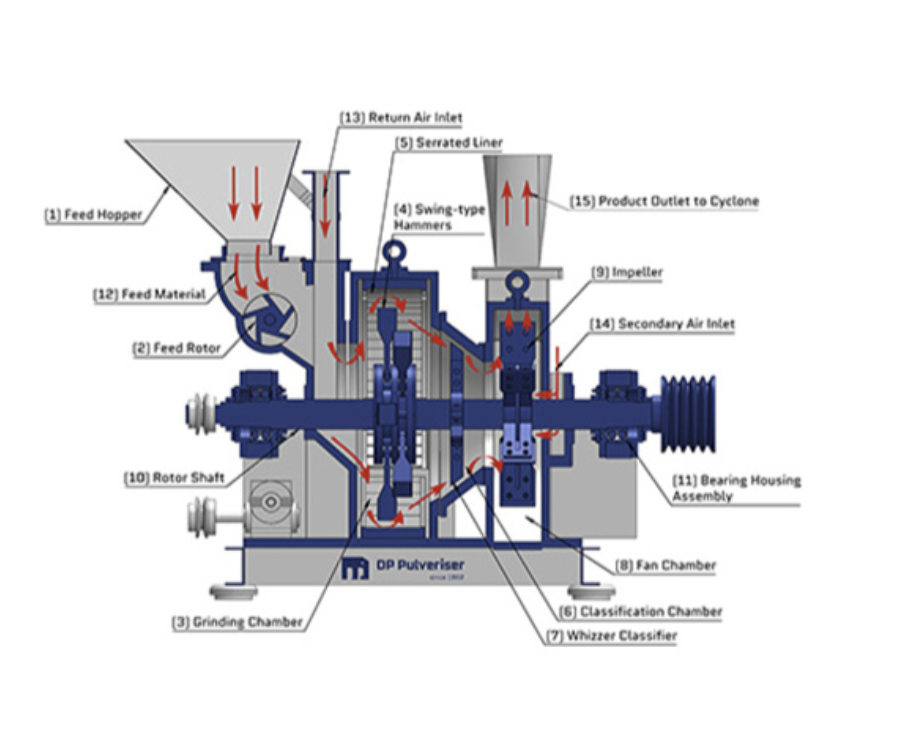

Operating on the principle of impact grinding, this marvel of engineering utilizes high-speed rotating hammers to shatter materials into tiny particles. These particles are then further processed through screens to achieve the desired fineness, ensuring unparalleled precision and consistency in output.

? Key Parts:

1. **Rotor Assembly**: Houses the rotating hammers responsible for pulverizing materials.

2. **Grinding Chamber**: Encloses the rotor assembly and provides space for material pulverization.

3. **Screen**: Determines the final particle size by controlling the exit of pulverized material.

4. **Feed Inlet and Outlet**: Facilitate the input and output of materials, ensuring smooth operation.

? Industries Benefitting from Impact Pulverizers:

1. **Chemical Industry**: From pigments to fertilizers, impact pulverizers efficiently process a wide range of chemical substances.

2. **Pharmaceuticals**: Precise grinding of pharmaceutical ingredients is essential for drug formulation, making impact pulverizers indispensable in this sector.

3. **Food Processing**: Spice grinding, flour milling, and other food processing applications benefit from the uniform particle size achieved by impact pulverizers.

4. **Mining & Minerals**: Impact pulverizers play a vital role in the mining industry, where they are used for crushing and grinding ores to extract valuable minerals.

5. **Plastics & Polymers**: Recycling and manufacturing processes rely on impact pulverizers to reduce plastic waste and produce uniform polymer powders.

In conclusion, the Impact Pulverizer stands as a testament to innovation and efficiency in industrial processes. Its versatility, precision, and reliability make it an indispensable asset across a spectrum of industries, driving productivity and ensuring quality outputs. Ready to elevate your operations? Embrace the power of the Impact Pulverizer today!

#IndustrialInnovation#Efficiency#PrecisionGrinding#mills#dppulverizer#permix