Efficient Industrial Mixer Cleaning with CIP Spray Balls: A Comprehensive Guide

Efficient Industrial Mixer Cleaning with CIP Spray Balls: A Comprehensive Guide

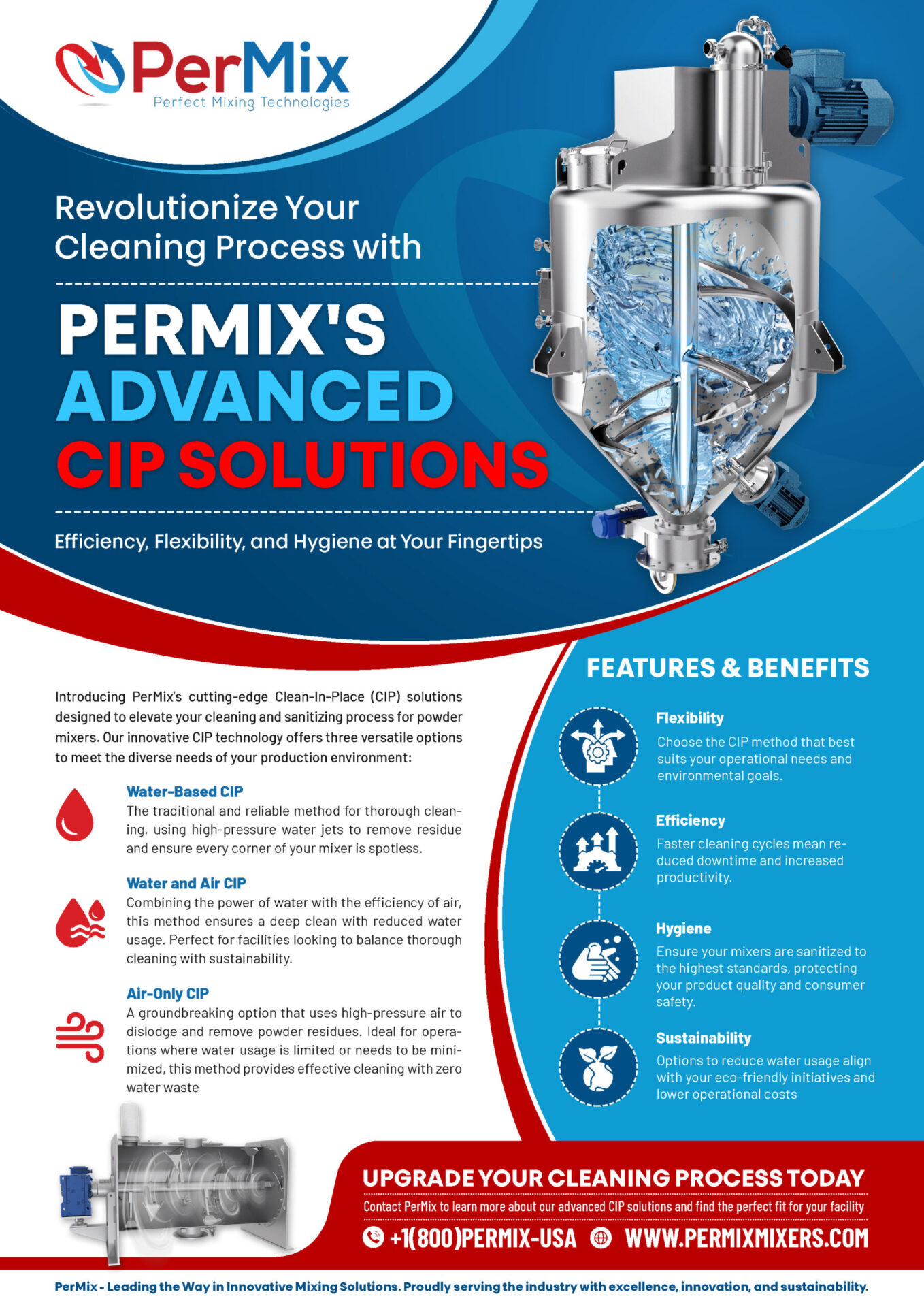

In industrial settings, maintaining the cleanliness of equipment like mixers is crucial for optimal performance and product quality. Clean-In-Place (CIP) spray balls have revolutionized the cleaning process, offering a seamless solution without the need for disassembly. In this comprehensive guide, we’ll explore how CIP spray balls effectively clean the inside of industrial mixers.

1. Understanding CIP Spray Balls for Industrial Mixer Cleaning

- Explore the fundamentals of CIP spray balls and their role in maintaining hygiene within industrial mixers.

2. Strategic Positioning for Maximum Coverage

- Learn how the strategic placement of CIP spray balls ensures thorough coverage, targeting areas prone to residue accumulation.

3. The Mechanics of Spraying: CIP System in Action

- Dive into the mechanics of CIP systems, examining how a pressurized flow of cleaning solution is sprayed through orifices to create a wide-reaching pattern.

4. Rotational Movement for Comprehensive Cleaning

- Explore the benefits of rotational movement in CIP spray balls, ensuring that every nook and cranny within the mixer receives effective cleaning.

5. Chemical Action: Choosing the Right Cleaning Solution

- Understand the importance of selecting the right cleaning solution, exploring the chemical composition that effectively breaks down residues and contaminants.

6. Temperature Control for Enhanced Cleaning

- Delve into the role of temperature control in optimizing the cleaning process, highlighting how elevated temperatures contribute to dissolving tough residues.

7. Rinsing Away Residues: The Final Step

- Learn about the crucial rinse cycle that follows the spraying process, ensuring the removal of all cleaning agents and residues.

8. Automation and Monitoring: Ensuring Consistency

- Discover how automation and monitoring play a key role in maintaining consistency and effectiveness throughout the CIP cleaning process.

9. Effluent Management: Handling Contaminated Water

- Explore the responsible management of effluent generated during the CIP process, emphasizing the proper treatment of contaminants before disposal.

Conclusion: Incorporating CIP spray balls into your industrial mixer cleaning routine not only ensures optimal hygiene but also minimizes downtime associated with manual cleaning and disassembly. Stay ahead in your industry by adopting this efficient and cost-effective solution for maintaining equipment cleanliness.